On-Demand Wire EDM Machining Services

We offer tight tolerances and complex wire EDM parts. IATF 16949:2016、ISO 9001:2015、ISO 14001:2015、ISO 27001:2022 & 13485:2016 Certified

Start a New EDM Quote

- All uploads are secure and confidential.

Advantages of using Wire EDM

Wire EDM is a non-traditional machining process in which metal is melted or vaporized by means of an electrical discharge, and is suitable for electrically conductive materials such as steel, titanium and brass, and is particularly suited to cutting hard metals. Its main advantage lies in its ability to process materials of all thicknesses and hardnesses, from thin sheets to hard alloys, and to cut complex shapes such as straight lines, arcs and cones.

Wire EDM offers a very high degree of precision, with an accuracy of up to 0.005 millimeters, and eliminates the need for special tooling changes, reducing the cost of consumables. Since the process itself does not touch the material, thermal deformation is low and material damage is effectively minimized.

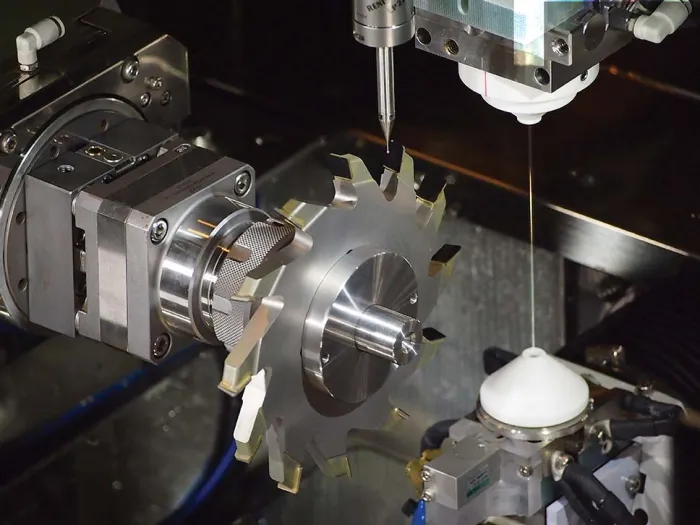

How Wire EDM works

Wire EDM machines work by utilizing a fine metal wire to cut through the workpiece. Wire EDM has two electrodes, and a high-frequency pulse current is applied between the two electrodes to generate a high-frequency electric field. At the same time, the wire electrode is connected to the workpiece, and the impact of the working fluid pushes the wire to the surface of the workpiece and completes the cutting.

During the Wire EDM process, many tiny white spots will be produced on the surface of the workpiece, which is due to the arc discharge between the wire and the workpiece. Wire EDM machines also have many functions such as automatic processing adjustment and cutting speed control, which can cut various metal materials with high accuracy and processing efficiency.

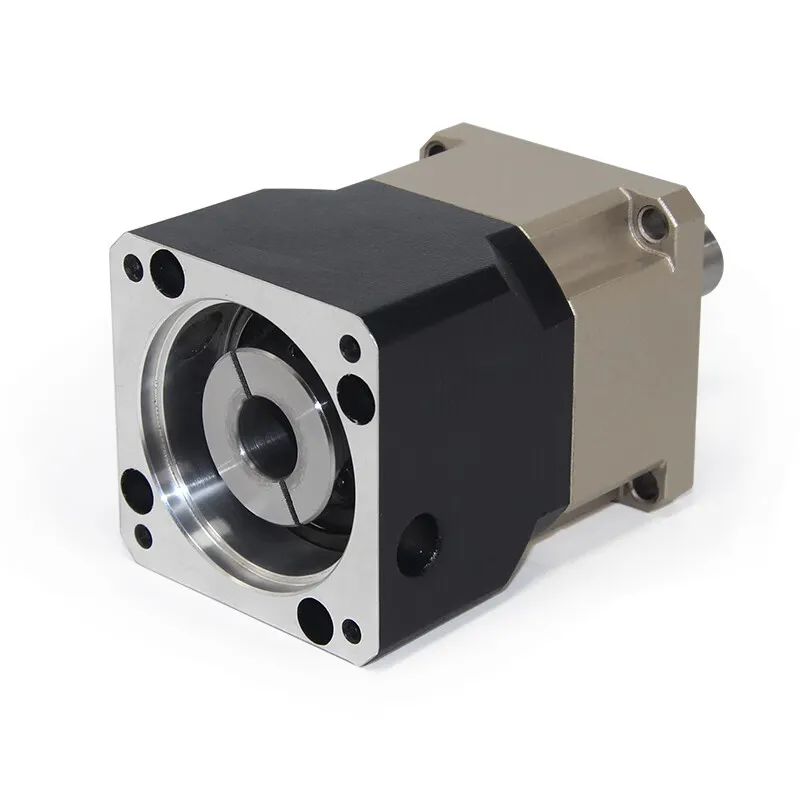

precision machining

We offer precision Wire EDM machining services, regardless of part complexity and tolerances.

Our Advantages

At Future Parts, we provide fast, high-quality and cost-effective manufacturing solutions tailored to your needs. Whether you are developing a prototype or scaling up production, we can turn your ideas into reality quickly and reliably.

- Global Reach

- Rapid Turnaround

- Comprehensive Services

- Cost Efficiency

- Certified Quality

- Tailored Solutions

Customer Testimonials

Learn more about what our customers say about us – Trustpilot

5/5

Altizer

engineers

This company from China can be trusted to deliver exceptional parts accurate to drawings and samples provided. I strongly recommend this company

5/5

Nancy

Procurement

We greatly appreciate the consistent quality and friendly service. Whenever we need parts urgently, they always respond quickly and solve our problem.

5/5

Max

Engineer

Friendly service with fast responses. They delivered our parts ahead of schedule, and the quality was excellent.

5/5

Campbell

Senior Manager

They have made a significant impact on our business—not only cost savings but also providing flexibility when we need it most.

Wire EDM Tolerances

We guarantee that all parts meet tight tolerances and fulfill the high standards required for all types of applications.

Small Parts

Medium Parts

Large Parts

Maximum Length

50 mm

100 mm

500 mm

Minimum Thickness

0.5 mm

1.0 mm

5.0 mm

Tolerance (allowed error)

±0.005

±0.01

±0.03

FAQs

Questions and Answers about Wire EDM

What is Wire EDM?

It is a precision machining method that cuts by generating high temperatures by discharging electricity between a metal workpiece and an electrode to melt and remove the workpiece material. This method does not use any cutting tools, but instead utilizes a fine metal wire as the electrode for cutting.

What is the purpose of Wire EDM?

Wire EDM is widely used in the fields of precision mold manufacturing, complex shape parts processing, and microfabrication of metal parts. It is particularly suitable for difficult-to-machine high hardness materials and complex geometries.

How accurate is Wire EDM?

The accuracy of Wire EDM can usually reach ±0.01mm, and for some high-precision machining it can even reach ±0.002mm. due to its contactless machining method, it can provide very high cutting accuracy, which makes it suitable for the manufacture of complex and fine parts.

Can Wire EDM cut tungsten?

It can cut hard materials such as tungsten. Due to the high hardness of tungsten, Wire EDM is one of the ideal choices for working with this type of material, being able to accurately cut tungsten and its alloys without damaging the tool.