Thread milling to make metal or plastic threads. It uses a rotary cutting tool that moves in a spiral path. This way, it can make the inside and outside very accurately. The tool follows a spiral path, so the engineer has more control than tapping. Many companies use thread milling for hard materials or large holes. The global market for these instruments was $1.2 billion in 2024. By 2033, it could grow to $2.5 billion.

Key Takeaways

Thread milling uses a rotary tool with a spiral motion. It makes very accurate inner and outer lines on many materials. This approach provides better control and higher thread quality. It also helps the tool to last longer than tapping. This is true for hard metals and large threads.

Choosing the right tools and Settings is very important. It helps stop errors, makes threads look better, and keeps tools working longer. Thread milling is best suited for CNC machines that move in three ways. It allows you to customize thread size and shape. Milling threads is slower and more difficult than tapping. But it saves costs by using fewer tools and less crushing.

Thread Milling Basics

What Is Thread Milling

Thread milling is a way to make threads in a workpiece. It uses a spinning cutting tool that moves in a spiral path. The main goal is to make both inside and outside threads very accurately. Many companies pick thread milling because it works for many thread types and sizes.

Tip: Thread milling can make threads in hard metals, soft alloys, and plastics. It is helpful for tough materials that might break a tap.

Some important things about thread milling are:

- The process uses a spinning multi-point cutting tool.

- It can make both inside and outside threads.

- One tool can make many thread sizes and types, so it is flexible.

- The process needs a CNC milling machine with special programming.

- Special thread milling cutters are made for this spiral cutting.

Thread milling is special because it can make many thread forms like ISO metric, American UN, British Standard, NPT, and ACME. It also lets you control how deep and what shape the thread is.

How It Works

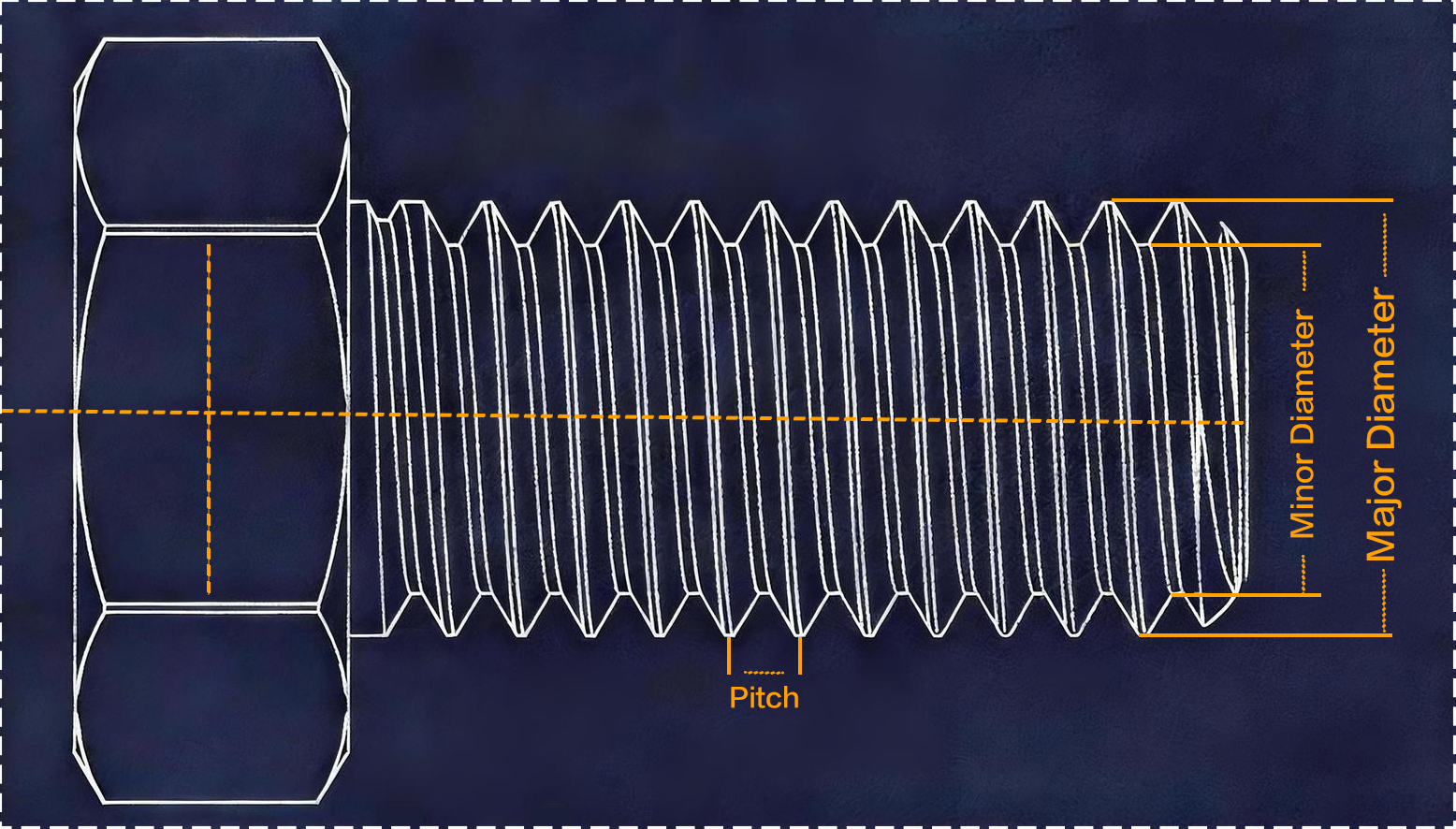

Thread milling uses a special tool movement called a helical toolpath. The cutter spins and moves in a circle around the hole or shaft. At the same time, it moves up or down along the Z-axis. This movement makes the thread shape.

| Aspect | Thread Milling (Helical Toolpath) | Other Threading Methods (Tapping, Single-Point Threading) |

|---|---|---|

| Tool Movement | Rotating cutter moves in a helical path around the hole or surface | Tool moves straight or spins into the material |

| Thread Formation | Tool spins and moves up or down for accuracy | Easier tool movements, often just spinning or moving straight |

| Thread Types | Makes both inside and outside threads | Mostly makes inside threads only (tapping) |

| Cutting Forces & Vibrations | Gradual cutting lowers forces and vibrations | Higher forces and more chance of tool breaking |

| Chip Evacuation | Better because of the spiral flute design | Not as good at removing chips |

| Material Suitability | Works with many materials, even hard metals | Works best with softer or normal materials |

| Precision & Surface Finish | Very precise and smooth finish | Usually less precise and not as smooth |

This process requires a CNC machine that can move in three ways simultaneously (X, Y, and Z axes). The tool follows a set path and drops a thread pitch for each full circle. This allows the operator to control thread size, spacing, and depth.

Thread milling can be done with single-point or multi-shape tools. A single point tool requires more than one processing to complete the thread processing. A variety of tools to complete the thread processing. The way you grind (climb or conventional) changes the finish and the length of time the tool is used.

Thread milling can process threads of various sizes, from tiny threads to huge threads. It can cut soft materials like aluminum as well as hard materials like Incon nickel or titanium. The process also allows you to make custom thread shapes. It is less likely to damage the tool, so it is safer against expensive or hard parts.

Note: Good chip removal and coolant are important for keeping threads accurate and tools in good shape.

Process

Tools Used

Thread milling uses special tools for different machining. These tools are made for certain materials and thread types. Choosing the right tool helps make good threads and keeps the tool working longer. The most common thread milling cutters are cemented carbide, high speed steel, ceramic and cubic boron nitride inserts. Each tool material works best for certain jobs.

| Insert Material | Characteristics | Typical Applications |

|---|---|---|

| Carbide Inserts | Very hard and tough; keeps its shape well | Used for steels, stainless steels, and other metals; good for cars, planes, and machines |

| High-Speed Steel (HSS) | Strong and can take hits; easy to sharpen | Used for small jobs, soft materials, and when saving money is important |

| Ceramic Inserts | Super hard and stays strong in heat | Used for fast cutting, hard materials, and parts that need to be exact |

| Cubic Boron Nitride (CBN) | Almost as hard as diamond; great for hard steels | Used for hard steel threads, very exact work, and big jobs |

Thread milling tools also have different shapes and coatings for each job:

| Thread Mill Type | Description | Ideal Applications/Features |

|---|---|---|

| Helical Flute Thread Mills | Used for inside and outside threads; works fast; spiral shape lowers cutting force | Good for hard and thin parts; makes a smoother finish |

| Straight Flute Thread Mills | Used for many jobs; one tooth for each thread | Cuts strong and fast; best when the machine is very steady |

| Single Profile Thread Mills | Has many flutes for different thread sizes and shapes | Good for long, thin holes; does not push hard on the sides |

| Coating/Finish | Properties | Use Cases |

|---|---|---|

| Titanium Nitride (TiN) | Hard and tough; lowers friction | Works with many kinds of materials |

| Titanium Carbonitride (TiCN) | Harder than TiN; better against wear and heat | Used for stainless steel, cast iron, and aluminum |

| Aluminum Chromium Nitride (AlCrN) | Handles heat very well | Used for airplane parts, nickel, titanium, cast iron, and carbon steel |

| Solid Carbide | Very stiff and handles heat well | Used for fast cutting on cast iron, plastics, and tough materials |

Thread milling tools can be single-point or multi-point. Single-point thread mills cut one thread at a time. They can make many thread sizes and shapes. Multi-point thread mills cut more than one thread at once. They are faster for big jobs. Many new thread mills let coolant flow through the tool. This keeps the tool cool and pushes chips out, which helps in deep or closed holes.

Tip: For the best results, machinists pick the strongest tool they can. They also use a thread mill that is about 30% smaller than the hole.

Steps

Thread milling follows careful steps to make good threads. Each step helps keep the tool safe and the threads smooth.

- Tool Approach

The tool starts above the hole. This helps the tool last longer and keeps the thread straight. - Depth Passes

If the thread is longer than the tool, the tool goes down in steps. It cuts from the bottom of each step up. This makes the tool work less hard and gives better threads. - Helical Interpolation

The tool moves in a spiral around the hole while going down. This makes the thread shape. The CNC machine moves the tool in three ways at once. - Entry and Cutting

The tool goes into the cut by curving in. Then it follows the spiral path to cut the thread. - Completion and Retraction

When the thread is done, the tool pulls out of the hole. This ends the job and leaves a clean thread.

Thread milling often uses fast spinning tools. Fast speeds help the tool follow the spiral path well. New machines can change the speed as needed to keep the cut smooth and lower shaking. This stops marks on the thread and keeps the cutting force even. Because of this, machinists can make great threads even in hard or tricky materials.

Note: Setting the right speed, tool shape, and cutting settings is very important for smooth, quiet thread milling. This helps make smooth threads and keeps the tool working longer.

Thread Milling vs. Tapping

Differences

Thread milling and tapping both make threads, but they do it differently. Thread milling uses a CNC machine to move a cutting tool in a spiral. This method works for inside and outside threads. The tool can change thread sizes by changing the program. Thread milling uses strong carbide tools. These tools last longer and can cut hard metals like titanium.

Tapping uses a tap tool that looks like a screw with grooves. The tap makes threads by turning into the hole. Tapping is best for inside threads and normal sizes. It is faster and easier but not as flexible. Tapping tools wear out faster. They do not work well for big or special threads.

| Aspect | Thread Milling | Tapping |

|---|---|---|

| Process | CNC-guided tool moves in a spiral to carve threads | Tap tool follows hole path, cutting threads by turning into the hole |

| Tool Design | Durable carbide tools, handles internal and external threads, adjustable | Tap resembles a grooved screw, for specific thread sizes, mainly internal only |

| Thread Size | No size limit, can handle large and custom threads | Best for small, standard thread sizes |

| Accuracy | High precision, adjustable thread size via programming | Less accurate, fixed size, sensitive to misalignment |

| Thread Quality | Higher quality threads, better surface finish and chip control | Rougher threads, more chip control problems |

| Speed | Slower process due to complex tool movement | Faster, straightforward cutting process |

| Applications | Precision, large, custom, hard material threads, internal & external | Quick, small, standard internal threads in softer materials |

| Cost | Higher initial investment, longer tool life, fewer tools needed | Lower initial cost, tools wear faster, many taps needed for different sizes |

Pros and Cons

Thread milling and tapping each have good and bad points. Here are some main ideas:

- Tapping finishes threads fast. For example, tapping a 1/4”-20 thread in mild steel takes 1-2 seconds. Thread milling the same thread takes about 10 seconds. The tool must move in and out slowly.

- Tapping is easy and good for lots of jobs with normal threads in soft metals. You need a different tap for each thread size. This means more tool changes.

- Thread milling uses one tool for many thread sizes and types. This helps when making big or special threads, or working with hard metals.

- Thread milling tools last longer. They do not wear out or break easily, even in tough metals or deep holes. The process makes short chips that come out fast. This keeps the tool safe and the thread smooth.

- Tapping tools wear out faster and can break in hard metals. Chips can get stuck in the tap. This can make rough threads or break the tool.

- Thread milling needs a CNC machine that can move in three ways. Not every shop has this machine. The process is slower and needs more power for big threads.

Tip: Thread milling is best for special threads, hard metals, and when you want high-quality threads. Tapping is better for fast, easy jobs with normal threads.

Advantages and Disadvantages

Benefits

Thread milling has many good points. It is great for jobs that need very exact work, like making airplane or medical parts. This process gives workers more ways to control how they make threads.

- Superior Precision and Consistency

Thread milling uses special CNC machines. These machines help make threads that are very exact every time. This is important for parts that must be perfect. - High Thread Quality

The process makes smooth threads. It does not make much heat or stress. This means the threads do not get bent and look better. - Lower Risk of Tool Breakage

Thread milling does not push hard on the tool or part. This makes it less likely for the tool to break or the part to get hurt. This helps the work go on without stopping. - Versatility Across Materials

You can use thread milling on many things. It works on aluminum, stainless steel, titanium, and plastics. This makes it good for lots of different jobs. - Better Chip Evacuation

The spiral way of cutting moves chips out fast. This is helpful for blind holes, where chips can get stuck and cause trouble. - Cost Savings

Thread milling tools last longer because they do not wear out fast. One tool can make many thread sizes. This means you do not need as many tools and can save money. The process also wastes less material, which saves even more.

Drawbacks

Thread milling also has some bad points, mostly when making lots of parts.

- Slower Production Speed

Thread milling takes longer than tapping. This can slow things down when you need to make many parts. - Complex Setup and Programming

The process needs skilled workers and harder CNC programs. This can take more time to set up and means workers need more training. - Higher Tooling Costs

Thread milling cutters cost more than taps. The higher price can make it less cost-friendly for simple jobs. - Not Ideal for All Jobs

For very big jobs where speed matters most, tapping might be better. Picking the wrong tool or setup can also make the job take longer and waste more.

Note: Companies should think about these bad points and good points before picking the best way to make threads.

Tips for Success

Tool Selection

Picking the right thread milling tool is very important. It helps make good threads and keeps the tool working longer. Machinists need to think about a few things before they choose a tool. They should check what thread standard is needed, like Metric, Unified, or NPT. They must know what the workpiece is made of, such as steel, stainless steel, or aluminum.

The right thread size and pitch are needed for each job. Machinists also need to see if the hole is blind or goes all the way through. They should think about how deep the thread is and how far the tool must reach. The tool’s material and coating must match the workpiece. Some coatings, like TiAlN or diamond-like carbon, help the tool last longer and lower friction.

The shape of the tool, like rake and helix angles, changes how it cuts and how smooth the thread is. Machinists should also think about what the part will do, like which way the load goes or if it will shake.

Tip: Tools with special coatings and the right shape work better in hard materials and last longer.

Setup

A good setup stops mistakes and keeps threads correct. Machinists should make sure everything is steady and lined up right. The table below shows some common setup mistakes and how to stop them:

| Common Error | How to Prevent It |

|---|---|

| Vibrations and Chatter | Use steady setups and holders that stop shaking |

| Tool Wear | Use coated tools and keep things cool |

| Thread Runout | Line up the tool and hold the workpiece tight |

| Depth Variability | Use strong holders and check the CNC program |

| Poor Clamping | Clamp the workpiece hard and use extra supports |

| Incorrect Programming | Check the CNC code and set up the machine right |

Common Mistakes

Some mistakes happen a lot in thread milling. These can make threads bad or break tools. Using too much force can make threads the wrong size or shape. Going too fast can chip the tool’s edge. If chips do not come out, the tool can break. Hitting the workpiece or fixture can hurt the tool. If the setup is not steady, it can make rough threads and chatter marks.

Machinists can stop these problems by going slower, using coolant inside the tool, and making sure the workpiece is held tight. If threads look rough or tools break, they should check if the tool is lined up, slow down, and use more passes. Fixing problems fast keeps the work safe and the threads looking good.

Note: Planning ahead and paying close attention helps machinists get the best results from thread milling.

Thread milling makes accurate threads in many materials and sizes. This method gives workers more choices and control. Many companies use thread milling for hard metals or big holes. It is also good when tool life and thread quality are important. Studies show thread milling helps use fewer tools and breaks less often. It also helps workers finish hard jobs faster. People should pick their threading method based on the material and thread size. They should also think about how many parts they need to make. For harder jobs, experts and new machines can help with tips and advice.

FAQ

What is the main difference between thread milling and tapping?

Thread milling uses a rotating tool that moves in a spiral path. Tapping uses a tool that cuts threads by turning straight into the hole. Thread milling works for more materials and thread types.

Can thread milling make both internal and external threads?

Yes. Thread milling can create both internal and external threads. The process uses the same tool for both types. This makes it flexible for many jobs.

Why do machinists choose thread milling for hard materials?

Thread milling puts less force on the tool and workpiece. This lowers the risk of tool breakage. Machinists use it for hard metals like titanium or stainless steel.

What CNC machines work best for thread milling?

CNC milling machines with three-axis movement work best. These machines control the tool’s spiral path. They help make accurate and smooth threads.