What is Selective Laser Sintering?

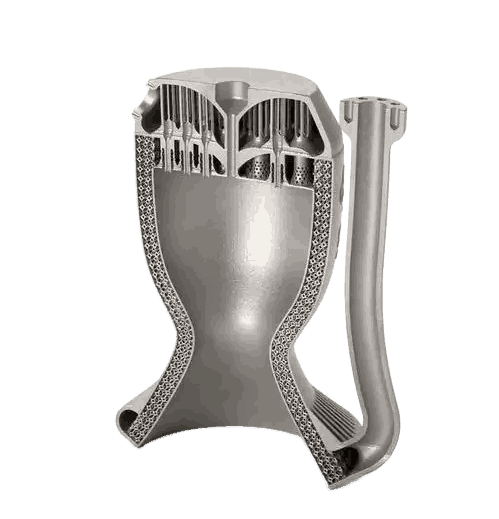

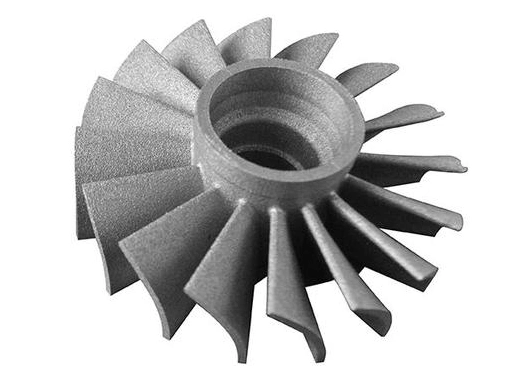

Selective laser sintering (SLS) is a technique that uses a laser to sinter fine polymer powder particles into a final 3D part. The printer heats up the powder particles so that the laser can better fuse the powders together to form a structure when it is excited.

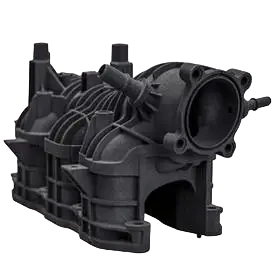

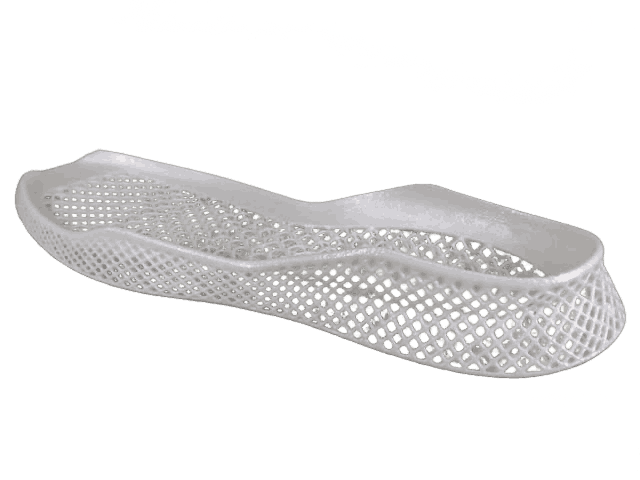

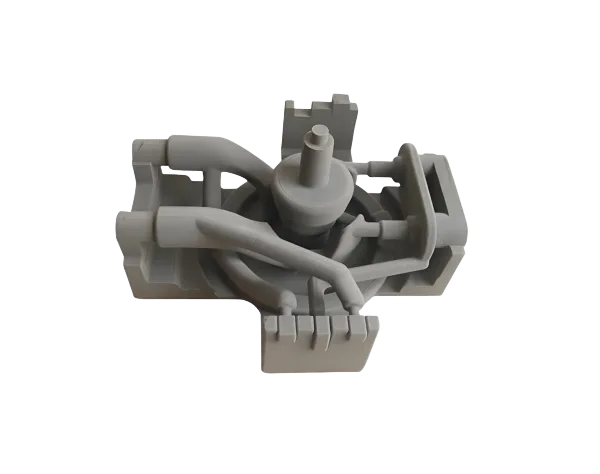

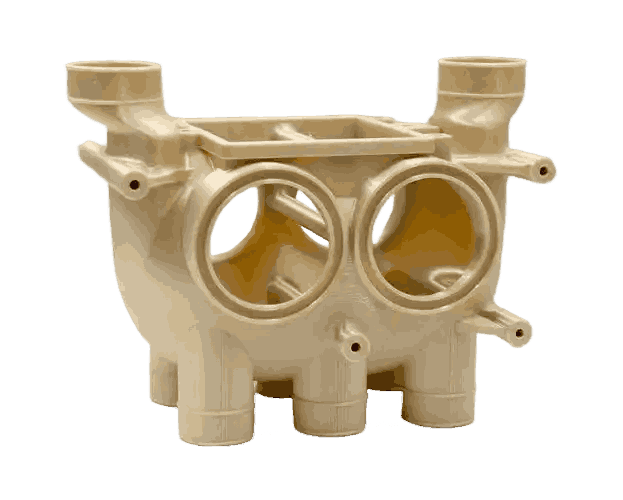

The unfused powder acts as a support for the part during the printing process, which is why it’s better suited to complex parts with barbs, thin walls, etc. than other printing techniques.

The most commonly used selective laser sintering material is nylon, a high-performance engineering thermoplastic that produces strong, rigid, sturdy, and durable parts. Nylon is UV, light, and heat resistant, which makes it ideal for many consumer engineering and medical industries.