What is SLA 3D Printing?

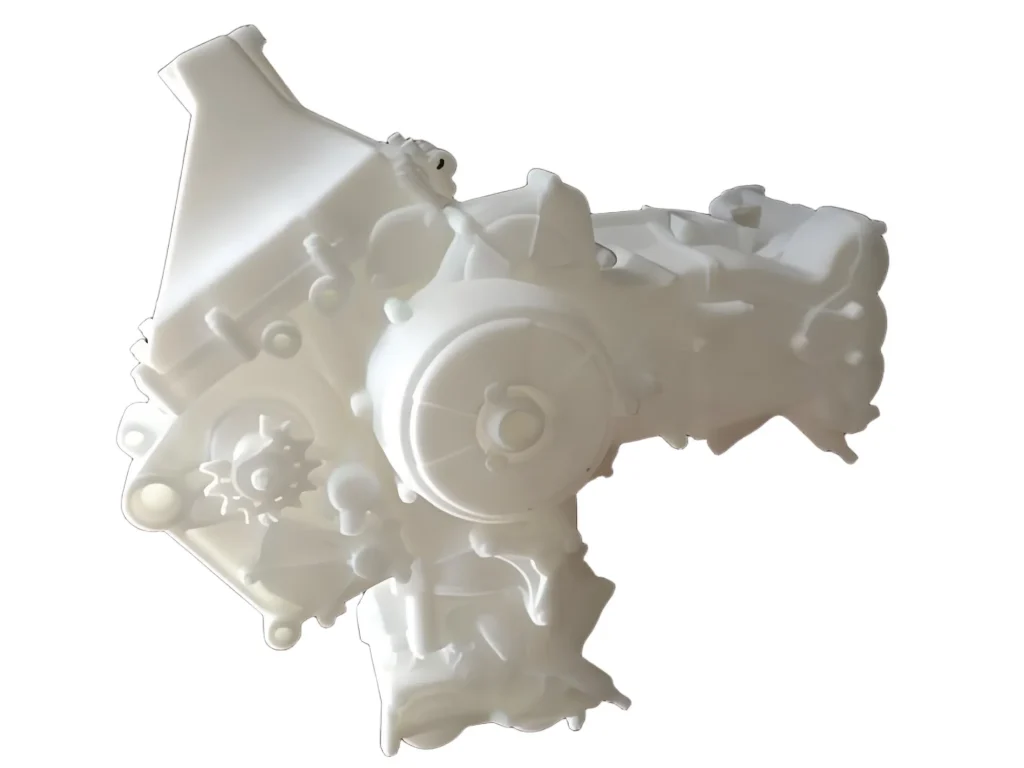

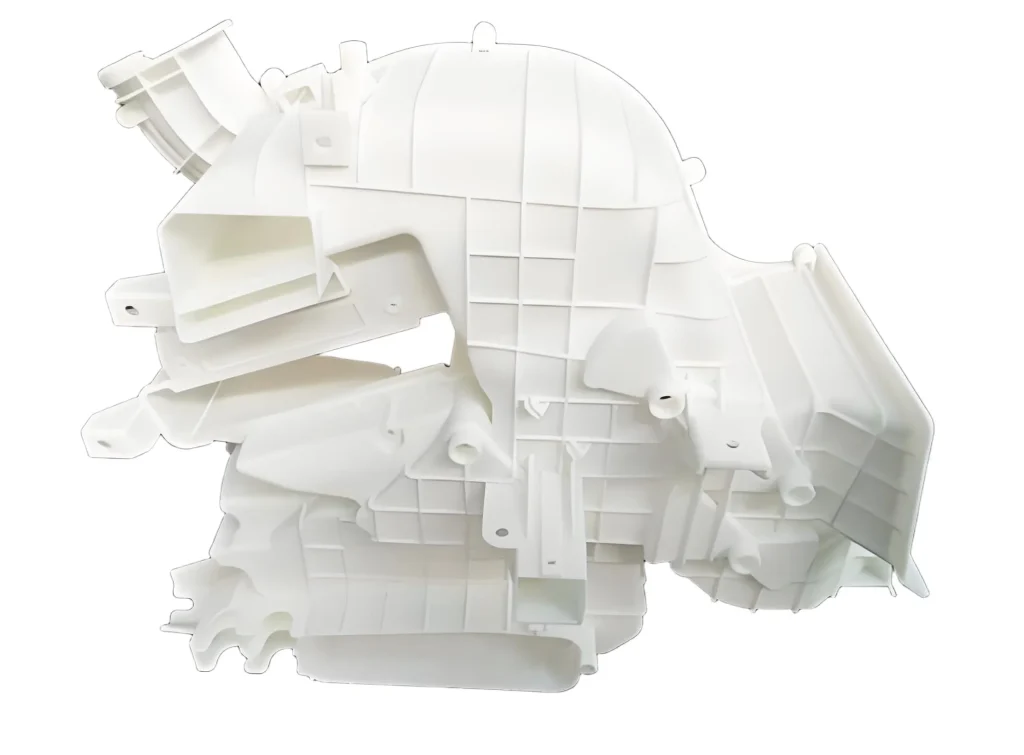

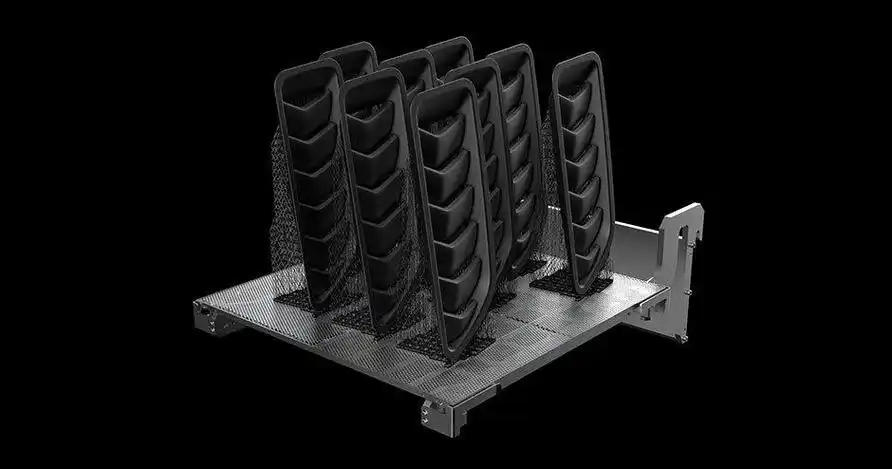

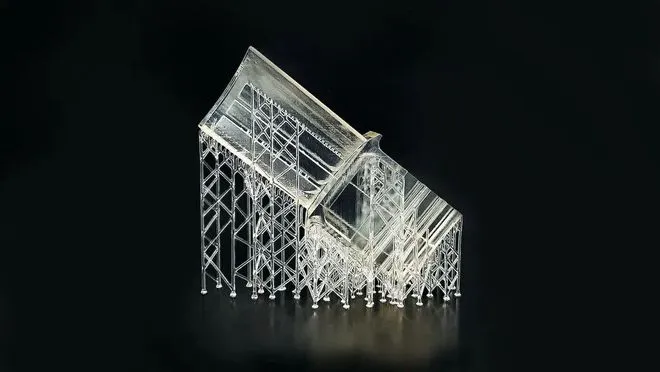

SLA (Stereolithography) is an additive manufacturing technology that uses ultraviolet (UV) light to cure liquid photosensitive resin layer by layer, building precise solid objects. This process is known as photopolymerization. SLA 3D printing is renowned for its excellent detail and smooth surface finish, making it ideal for producing high-precision prototypes and parts with complex geometries.