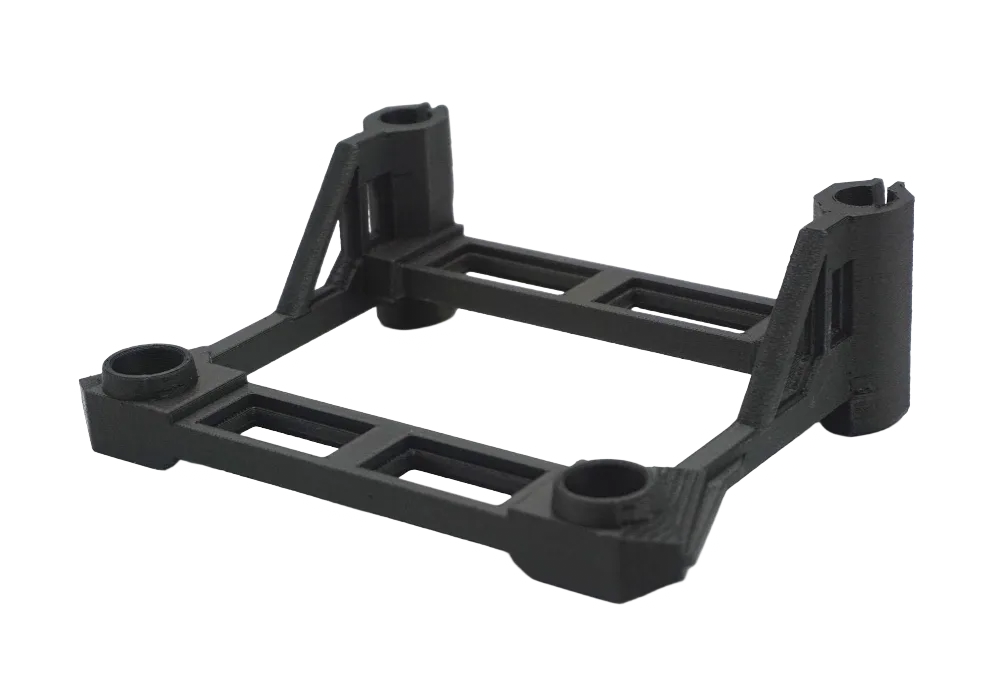

About FDM 3D Printing

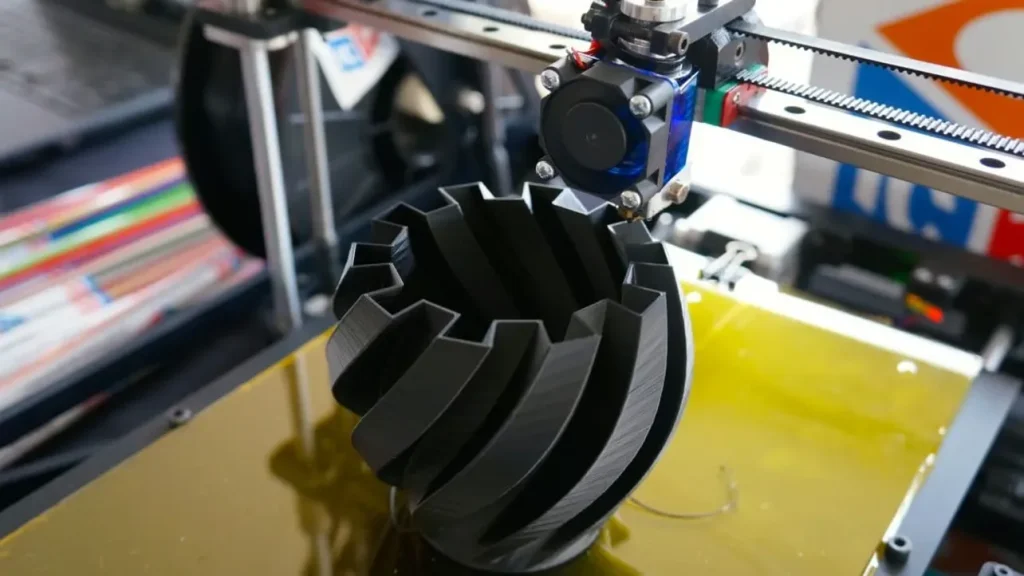

FDM, or Fused Deposition Modeling, works by heating plastic filaments until they melt, then extruding them through a nozzle to build up layers one by one until the desired part is formed. It is a type of rapid prototyping technology.

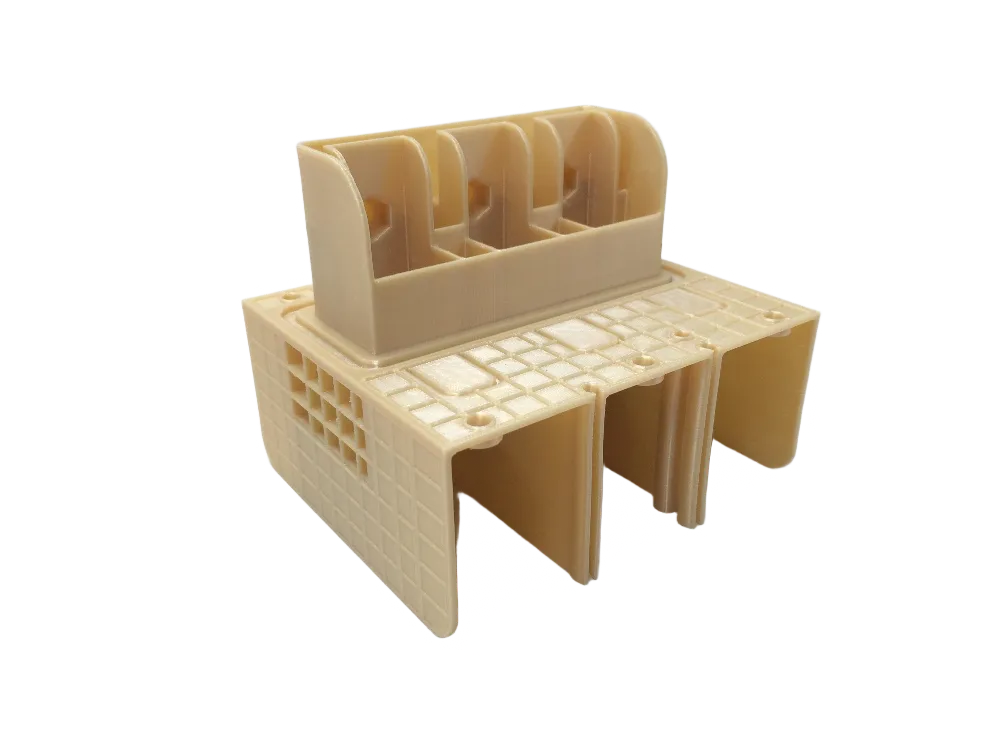

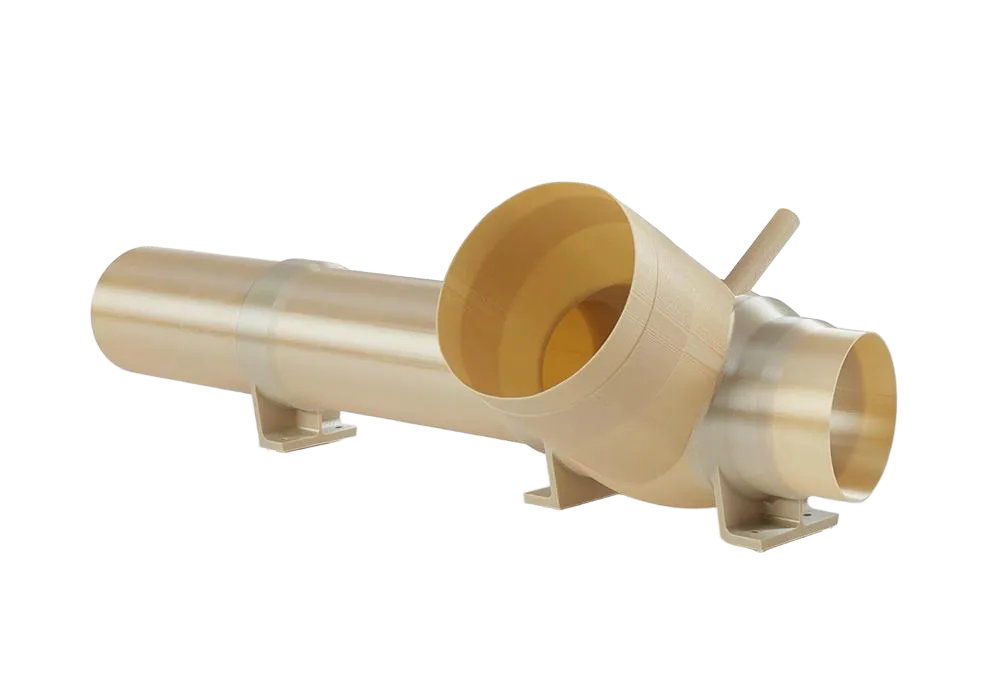

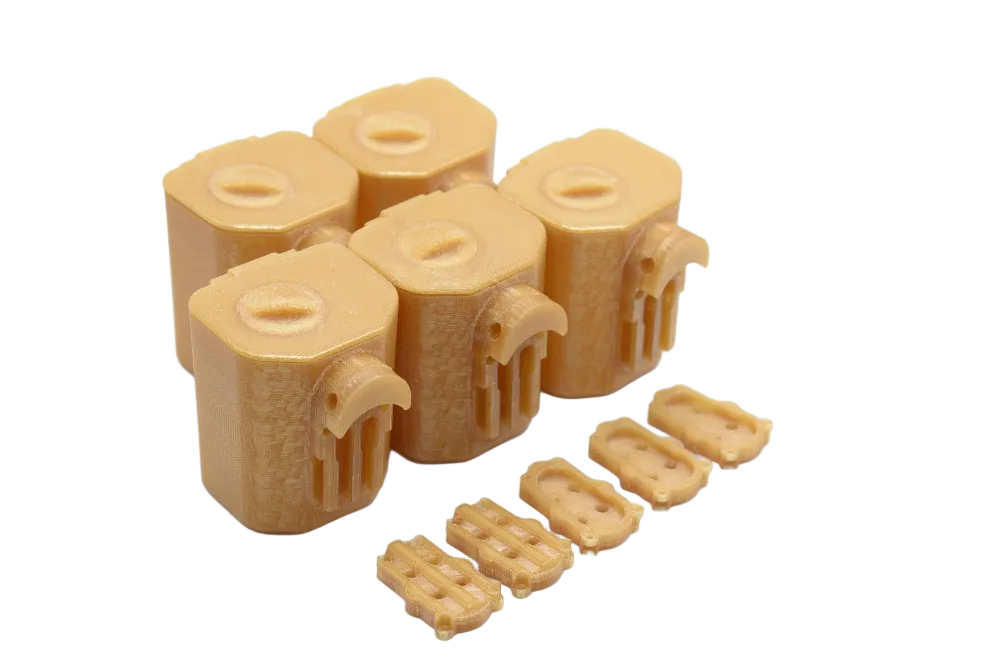

Fused deposition modeling is often used by companies to test the functionality of products in the early stages of development, which greatly helps to promote innovation and shorten the new product development cycle.