CNC Machining bronze service

CNC bronze processing involves creating precise parts from bronze alloys using advanced computer-controlled machines. Machining bronze is ideal because bronze is very strong and resists wear even in tough environments. Aluminum bronze and Alloy 932 are especially effective for demanding applications like bearings and bushings. Compared to brass, bronze doesn’t rust as quickly and can withstand higher pressure. Additionally, bronze conducts heat efficiently, making it useful for cooling electrical components. Selecting the right alloy in CNC bronze processing impacts performance, cost, and suitability for specific tasks.

Key Points

- CNC bronze machining uses computers to control machines. These machines make strong and exact parts. The parts do not wear out or rust easily.

- Picking the right bronze alloy is important. Phosphor bronze or aluminum bronze can make parts work better. They can also help lower the cost of making parts.

- Bronze parts last a long time. They work well in hard places like aerospace, and boats.

CNC Bronze Processing

Key Benefits

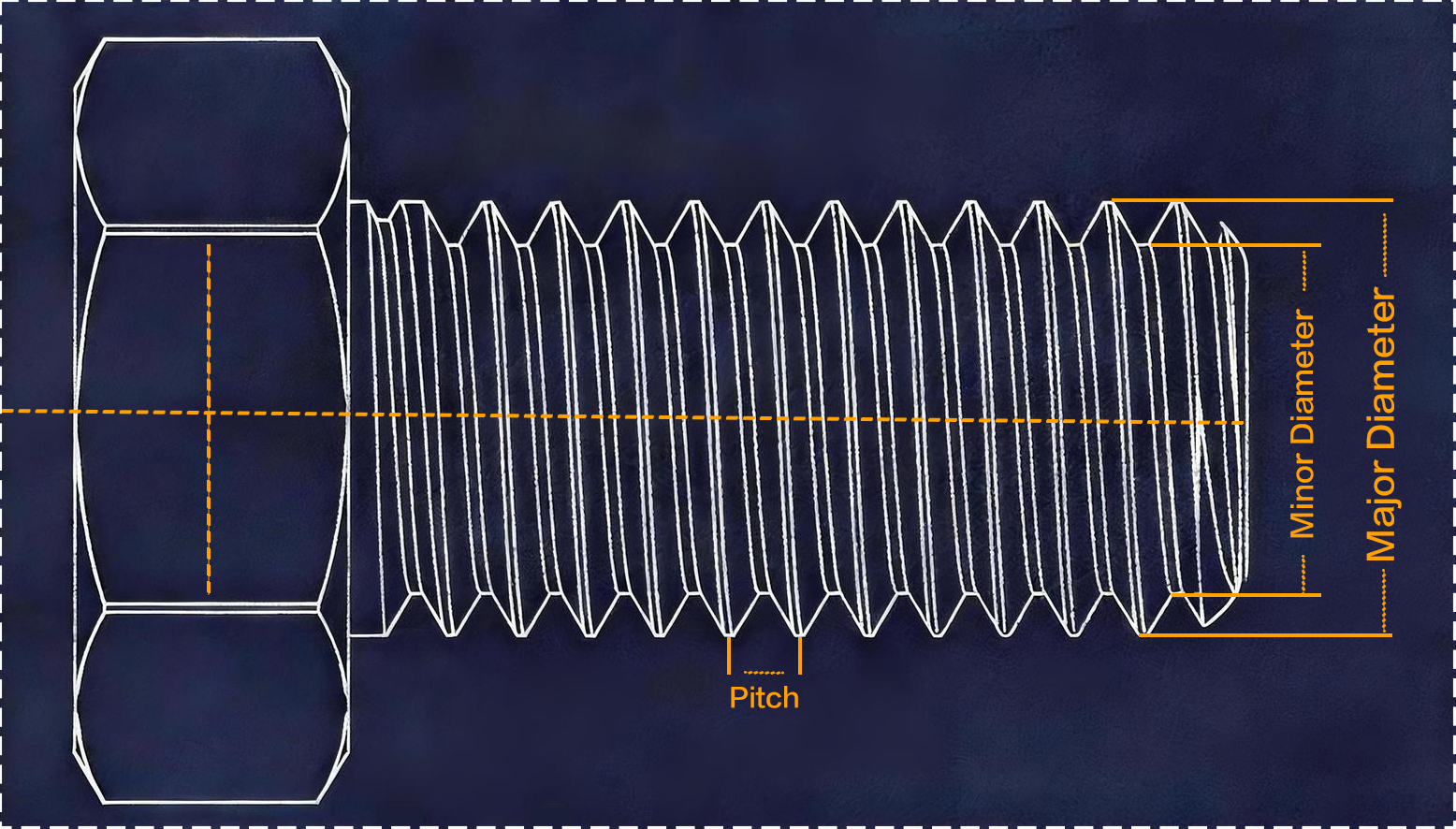

CNC bronze processing makes parts very exact and the same every time. Most bronze parts are made within ±0.05 mm to ±0.10 mm of the right size. Some special parts, like bearings and gears, can be even closer, at ±0.01 mm or better. Phosphor and aluminum bronze alloys can be made even more exact because they are very stable. This accuracy is important for things like planes, cars, and medical tools. Bronze does not rust easily and does not wear out fast. This means the parts last longer. Bronze also lets heat and electricity move through it well. That makes it good for both electrical and mechanical uses.

Typical Applications

Many industries use CNC bronze processing. The aerospace industry uses bronze for airplane parts, engine mounts, and hydraulic fittings. Bronze is strong and does not rust, so it works well here. Car companies use bronze bushings and bearings in steering, suspension, and drivetrain systems. Bronze makes these parts last longer and work smoothly. Medical device makers use bronze for implants and surgical tools. Bronze is safe and does not rust, so it is good for medical uses. The table below shows where bronze parts are used:

| Industry | CNC Machined Bronze Parts | Reasons for Use |

|---|---|---|

| Aerospace & Defense | Aircraft parts, engine mounts, hydraulic fittings | Strength, longevity, corrosion resistance |

| Automotive | Bushings, bearings in steering, suspension, drivetrain | Durability, smooth operation, minimal lubrication |

| Medical Devices | Implants, surgical tools, medical components | Corrosion resistance, safety, durability |

CNC bronze processing helps these industries by making strong and reliable parts.

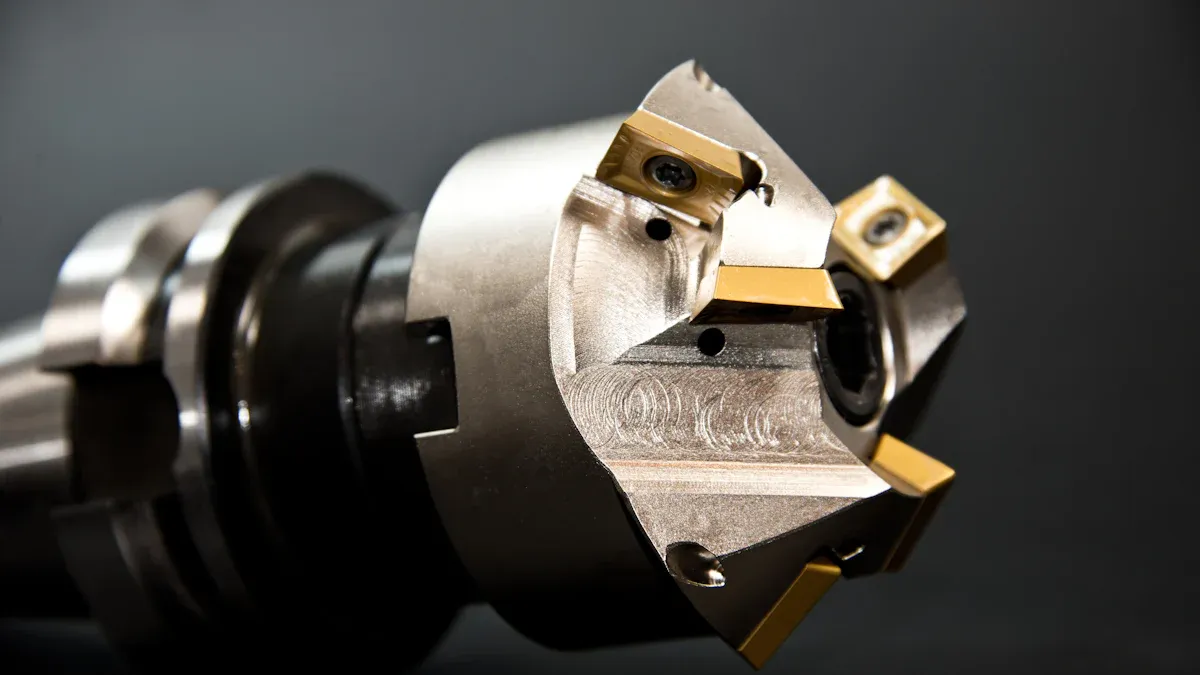

Machining Process

Steps Overview

CNC machining of bronze parts uses many careful steps. First, workers get the bronze ready. They cut it into smaller pieces with saws or shears. Then, they set up the machines. They pick the right speed and feed for the bronze alloy. The process has several main operations:

- Turning: Workers use a lathe to make round parts like bushings. They make sure the parts are even and smooth.

- Milling: Milling machines cut, drill, and shape plates. They add things like slots or holes for mounting.

- Drilling and Boring: Workers make holes and spaces that are very exact.

- Grinding: This step makes surfaces smooth and the right size.

- Finishing: Workers remove sharp edges and polish the parts.

- Inspection: Technicians check the parts to see if they are the right size.

- Cleaning: Workers clean off chips and coolant. This gets the parts ready to be put together.

Bronze Alloy Types and Applications

Bronze alloys have many types. Each type has special features. Makers pick alloys for strength, corrosion resistance, and machinability. The most used alloys in CNC machining are C932, C954, C863, C510, 642 bronze, and PB1. All these alloys have copper as the main part. Other metals are added to give extra qualities.

| Alloy Name | Chemical Composition (Approximate) | Typical Applications and Properties |

|---|---|---|

| C932 Tin Bronze | Copper, tin, iron, zinc | Bearings, bushings; wear resistance, machinability, cannot be heat-treated |

| C954 Aluminum Bronze | 82.7% Cu, 9-14% Al, 4% Fe | Bushings, gears, marine; high strength, corrosion resistance |

| C863 Manganese Bronze | 60-68% Cu, 25% Zn, 3-7.5% Al, 2.5-5% Mn, 2-4% Fe | Aerospace, marine, heavy-load bearings; very strong, wear resistant |

| C510 Phosphor Bronze | 95% Cu, 0.5-11% Sn, 0.01-0.35% P | Springs, bolts, connectors; toughness, wear resistance |

| 642 Bronze | Copper, tin, lead | Bolts, gears, valves; high strength, corrosion resistance, easy machinability |

| PB1 Phosphor Bronze | Copper, tin, phosphorus | Bearings, bushings; free machining, tough, high precision |

Performance Comparison

Bronze alloys are different in strength, price, and best uses. C932 bearing bronze is cheap and easy to machine. It works well for bushings and bearings in cars and machines. C954 aluminum bronze is stronger and resists rust. It is good for marine and heavy-duty parts. C863 manganese bronze is very tough and resists wear. It is used for hard jobs with big loads and fast speeds, like gears and hydraulic parts. It costs more to machine.

Phosphor bronze, like C510 and PB1, is great for very exact work. It does not wear out fast and keeps tight sizes. It is used for electrical connectors and springs. 642 bronze is strong, bends easily, and resists rust. It can be machined quickly and works well for bolts, gears, and valves.

| Alloy | Best For High Precision | Most Cost-Effective | Needs Special Tooling | Application Suitability |

|---|---|---|---|---|

| C932 | No | Yes | No | Bearings, bushings |

| C954 | Sometimes | No | Yes | Marine, gears, bushings |

| C863 | No | No | Yes | Heavy-load bearings, gears, hydraulics |

| C510/PB1 | Yes | Sometimes | No | Springs, connectors, bearings |

| 642 Bronze | Yes | Sometimes | No | Bolts, gears, valves |

FutureParts Bronze Machining Services

If you have a design ready, upload it here for a quote comparison. FutureParts not only provides CNC machining services, but also helps you select the appropriate machining method and optimize your project budget.

Our five-axis CNC machining center can transform complex 3D models into reality with exceptional precision. We can help you successfully complete your CNC bronze machining project.