Have you ever wondered how the metal parts of cars, kitchen appliances, and even the tiny connectors inside your cell phone are made? Many of them are likely made through an extremely important process called metal stamping process. This process quickly and accurately shapes flat sheets of metal into a variety of useful items.

Metal stamping is an important part of manufacturing today. It is so vital that the global metal stamping market was valued at approximately $243.93 billion in 2024! Experts believe that it will continue to grow. According to a report by Grand View Research, the market is expected to be worth more than $316.72 billion by 2030. This growth indicates that metal stamping is vital to industries such as automotive, electronics, and healthcare across the globe.

But what exactly is metal stamping? Why is it so popular? How does it work? Let’s delve into this fascinating world and explain it in depth.

What Exactly is Metal Stamping?

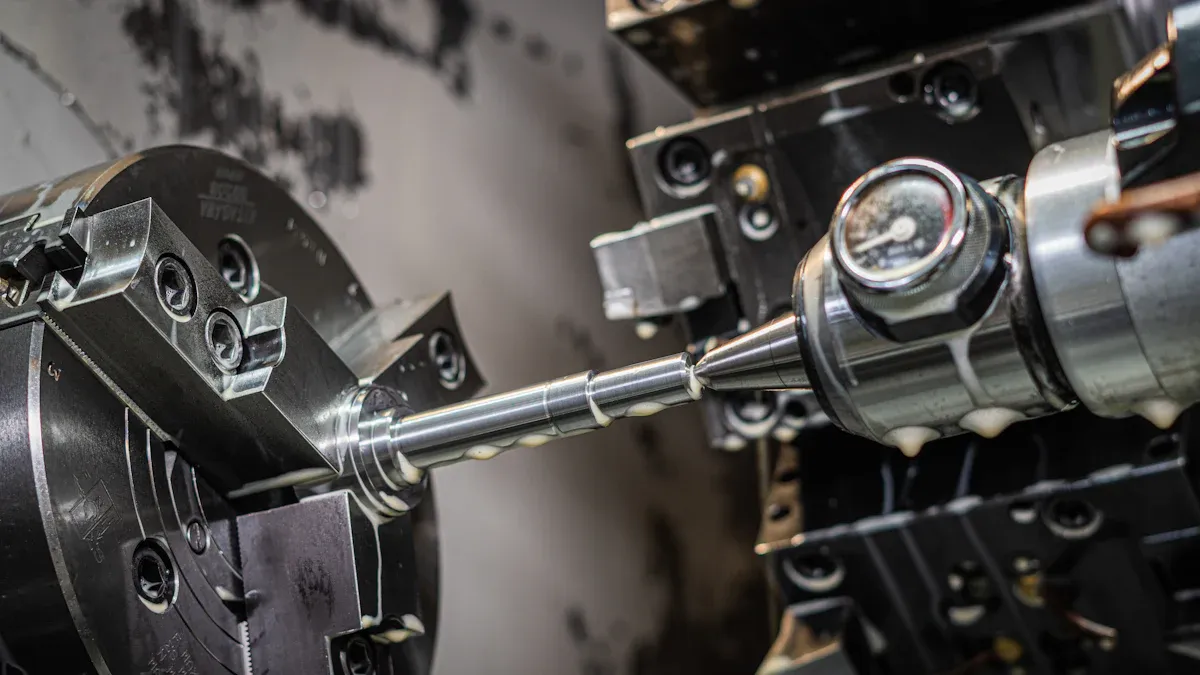

Metal stamping (or stamping for short) is a manufacturing process in which a flat sheet of metal is formed into a desired shape by extruding it, which is different from CNC machining, in which a tool extends a path and cuts to get the desired part, whereas stamping is done using a machine called a press, a special tool called a die, and the sheet metal fabrication itself (usually in the form of large rolls called coils, or precut flats called blanks pieces) to accomplish it.

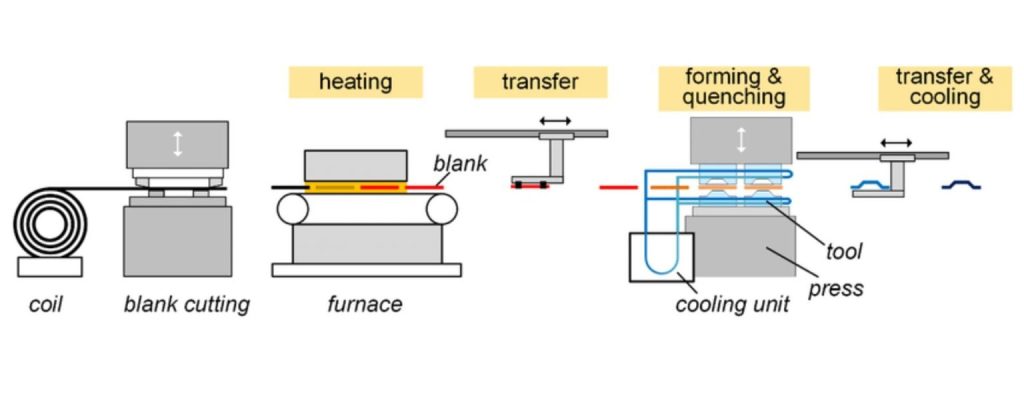

The press pushes the die against the metal with great force and then cuts and shapes the metal into the desired part. This is usually a “cold forming” process, meaning that the metal is not heated before it is formed, although sometimes heat may be required for certain materials or complex shapes.

Metal stamping is a key part of the broader field known as sheet metal fabrication, which includes various methods of cutting, bending and assembling sheet metal into structures or products.

How Does the Metal Stamping Process Work? (The Basic Steps)

Making stamped metal parts may seem complicated, but we can break it down into a few major steps. The exact steps depend on the part to be made:

- Putting in the metal: Long strips of sheet metal (from coils) or individual flat blanks are put into the press.

- Punching: This is usually the first step, where the die cuts the basic contour of the part from the sheet metal strip. The cut out part is called a “blank”.

- Piercing: If the part requires holes to be punched (such as for mounting screws), the piercing machine punches out the holes.

- Bending: This step creates an angle or curve in the metal. The press uses a die to bend flat metal along a specific line.

- Forming: This refers to shaping the metal beyond simple bending. It involves stretching or compressing the metal to form shapes such as curves, ribs (for strength), or specific features.

- Stretching: This is a special type of molding method used to create deep cupped shapes. A press pushes a punch into the metal, forcing it into the mold cavity. Stretching is needed to make metal sinks or soda cans. Sometimes, making very deep parts (deep drawing) exposes the metal to the severe stresses of metal stamping materials, which requires careful design and selection of materials.

- Extrusion: This step uses high pressure to squeeze metal to create fine details, sharp corners, or harden surfaces.

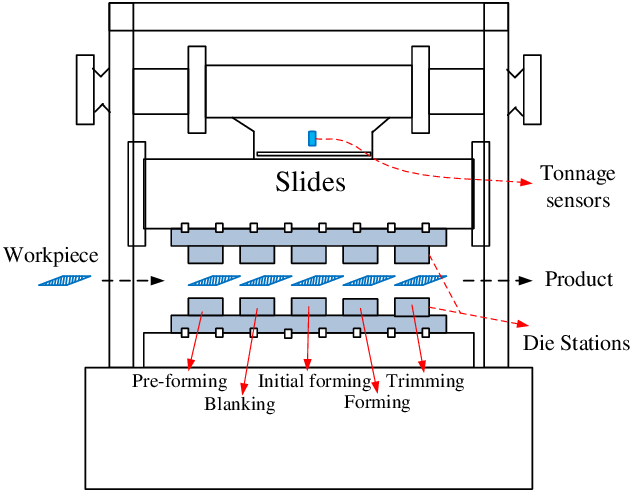

These operations are performed one by one on a single die stamping machine using complex dies, so the metal stamping process is very efficient in producing large quantities of parts.

Different Types of Metal Stamping

Not all stamping jobs are created equal. Depending on the complexity of the part and the quantity that needs to be manufactured, different types of stamping methods will be used:

- Progressive die stamping: This is like an assembly line inside a press. A roll of metal strip is fed through the press, and at each “station” within the die, a different action (such as piercing, bending, or punching) occurs. The strip is gradually moved through the stations until the finished part finally emerges. Progressive die stamping is ideally suited for the rapid manufacture of large quantities of small, complex parts.

- Transfer Die Stamping: In this method, the part is first cut (stamped). Then, mechanical “fingers” or arms pick up the part and transfer it from one station within the press to the next. Each station has a different die that performs a specific operation. Transfer die stamping is typically used for larger parts, such as automotive body panels, which may not work well on metal belts.

- Quad Slide or Multi Slide Stamping: This technique is a little different. Instead of just an up and down motion like regular stamping, it uses multiple moving slides (usually four, hence the name) that enter from different directions (top, bottom, side). This allows for very complex bending and molding, perfect for complex parts like springs, clips, and electrical contacts commonly found in electronics.

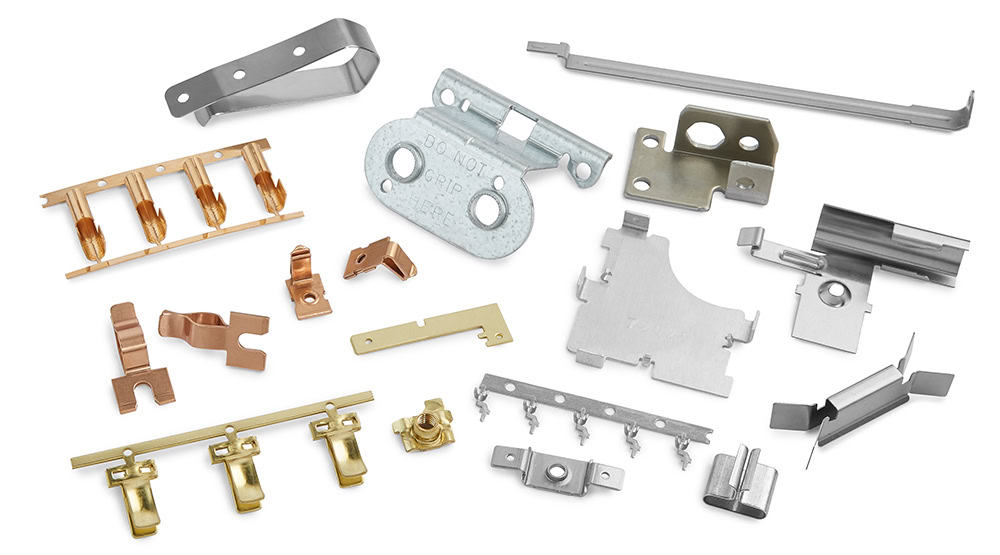

What Materials Can Be Stamped?

The advantage of metal stamping is that it works with a wide variety of metals. The choice depends on what the final part needs to do.

Some common materials include:

| Material | Properties | Common Applications |

|---|---|---|

| Steel | Very strong and cost-effective. Includes stainless steel (rust-resistant) and carbon steel. | Automotive, appliances, construction |

| Aluminum | Lightweight and corrosion-resistant. | Automotive (weight reduction), aircraft, electronic housings |

| Copper | Excellent electrical conductor. | Electrical contacts, wires, connectors |

| Brass | Alloy of copper and zinc. Easy to form, attractive appearance, corrosion-resistant. | Plumbing fixtures, decorative items |

| Titanium | High strength, lightweight, and corrosion-resistant even at high temperatures. | Aerospace, medical implants |

| Nickel Alloys | Perform well in extreme temperatures and harsh environments. | Aerospace, chemical processing |

Where Do We See Metal Stamping? (Applications)

You may be surprised at how many things around you are made using this process . It is used in almost every industry! Here are a few examples:

- Automotive: Body panels (doors, hoods, fenders), brackets, engine parts, seat structures, exhaust parts. Custom metal stamping is used extensively here to achieve unique part designs.

- Aerospace: Aircraft fuselage components, engine components, brackets, fasteners. Precision, strong, lightweight materials are key.

- Electronics: Computer housings, smartphone frames, connectors, terminals, component shields, heat sinks. Precision metal stamping is critical for these tiny, complex parts.

- Medical: Surgical instruments, diagnostic equipment components, some implantable parts (e.g., pacemaker housings). Cleanliness and high precision are critical.

- Appliances: Housings, internal brackets and components for washing machines, dryers, refrigerators, microwave ovens.

- Construction: Brackets for connecting wood beams, electrical boxes, hardware such as hinges and latches, HVAC system components.

- Industrial equipment: housings, brackets, levers, gears and parts for all types of machinery.

Basically, if something is made from metal forming sheet metal, there is a good chance that metal stamping is involved !

Why Choose Metal Stamping? (Advantages)

There are good reasons why metal stamping is so widely used:

- Cost Effective (for high volume production): Once the initial tooling is made (which is often expensive), the cost per part becomes very low when producing thousands or millions of parts.

- Fast and Productive: Stamping presses operate at very high speeds, in some cases producing hundreds or even thousands of parts per minute.

- Consistency and Accuracy (Repeatability): A stamping die ensures that each part produced is virtually identical to the last, thus maintaining high quality and tight tolerances (i.e., allowing for very small variations).

- Material Versatility: As we have seen, it is suitable for many different metals.

Complex shapes can be processed: Although there are certain limitations, metal stamping can produce quite complex shapes, including deep shapes that may experience the harsh metal forming conditions of metal stamping, which require specialized design and process control.

Future Parts : Your Custom Metal Stamping Experts

Many projects require more than just standard off-the-shelf parts like washers. When you need unique metal parts designed and manufactured for a specific application, Future Parts is at your service.

We specialize in custom metal stamping, translating your unique design and specific requirements into high-quality precision metal parts. Our service process includes:

- Requirements Consultation: We will work with you to fully understand the design intent, functional requirements, material selection and expected yield of the part.

- Tooling Design and Manufacturing: Our team of experts will design and manufacture the high precision, customized tooling you need for production. We are experienced in this critical aspect of ensuring part quality and efficiency.

- Prototyping: We produce small quantities of samples for you to test and verify the accuracy of your design and mold.

- Mass Production: After receiving your approval, we efficiently conduct full-scale mass production to ensure on-time delivery.

When you need parts that cannot be purchased directly from the market, or have special requirements for characteristics, materials, and tolerances, choosing Future Parts’ custom metal stamping services is the ideal solution. We are committed to being a reliable partner who understands your needs and ensures the success of your project.

Challenges and Considerations in Metal Stamping

Although powerful, it’s not suitable for all situations. Here are some things to keep in mind:

Initial Tooling Costs: The cost of designing and building a tool can be high, especially for complex parts or progressive dies.

Design Limitations: Extremely complex three-dimensional shapes may be better suited for other processes such as casting or CNC machining. There are limits to the extent to which metal can be bent or stretched without tearing or creasing. Processes that involve severe deformation of the metal stamping process (e.g., deep drawing) will push these limits.

Tooling Lead Time: Time is required to design, build and test tooling before production can begin.

Thickness of Materials: Stamping is usually best suited for relatively thin metal sheets (but “thin” can range from aluminum foil to thicker plates, depending on the stamping press).

Potential Defects: If the process is not set up properly or if the dies are worn, problems such as burrs (sharp edges), cracks or creases may occur.

The Future of Metal Stamping

Metal stamping hasn’t stood still. It has evolved along with technology:

Automation and Robotics: Robots are increasingly being used to load, unload and transfer parts, increasing speed and safety.

SIMULATION SOFTWARE: Advanced computer programs can help engineers design better dies and predict how metal will behave during stamping, resulting in less trial and error.

Lighter, stronger materials: Demand for lighter vehicles and products is driving innovations in stamping technologies for new alloys such as advanced high-strength steels (AHSS) and aluminum alloys.

Higher Precision: Tighter tolerances required by industries such as electronics and medical are further driving the development of precision metal stamping capabilities.

Integration: Stamping is often integrated into stamping lines with other processes such as laser welding, tapping (making threads) or assembly.

Conclusion

Metal stamping, one of the pillars of modern manufacturing, has an impact on every aspect of our daily lives, from the car you drive to the kitchenware in your home.

Through the use of powerful presses and well-designed molds, it shapes everything from basic brackets to complex electronic components. Whether it’s progressive die stamping for mass production or custom metal stamping for specialized parts, this technology is the foundation of manufacturing.