CNC milling is a kind of material processing through the computer’s control machine, it belongs to a kind of process of material reduction, this process is generally suitable for processing some round products, through the CNC milling processed out of the product has a high degree of precision, which is why a lot of industries are using its application.

What is CNC Milling Machining?

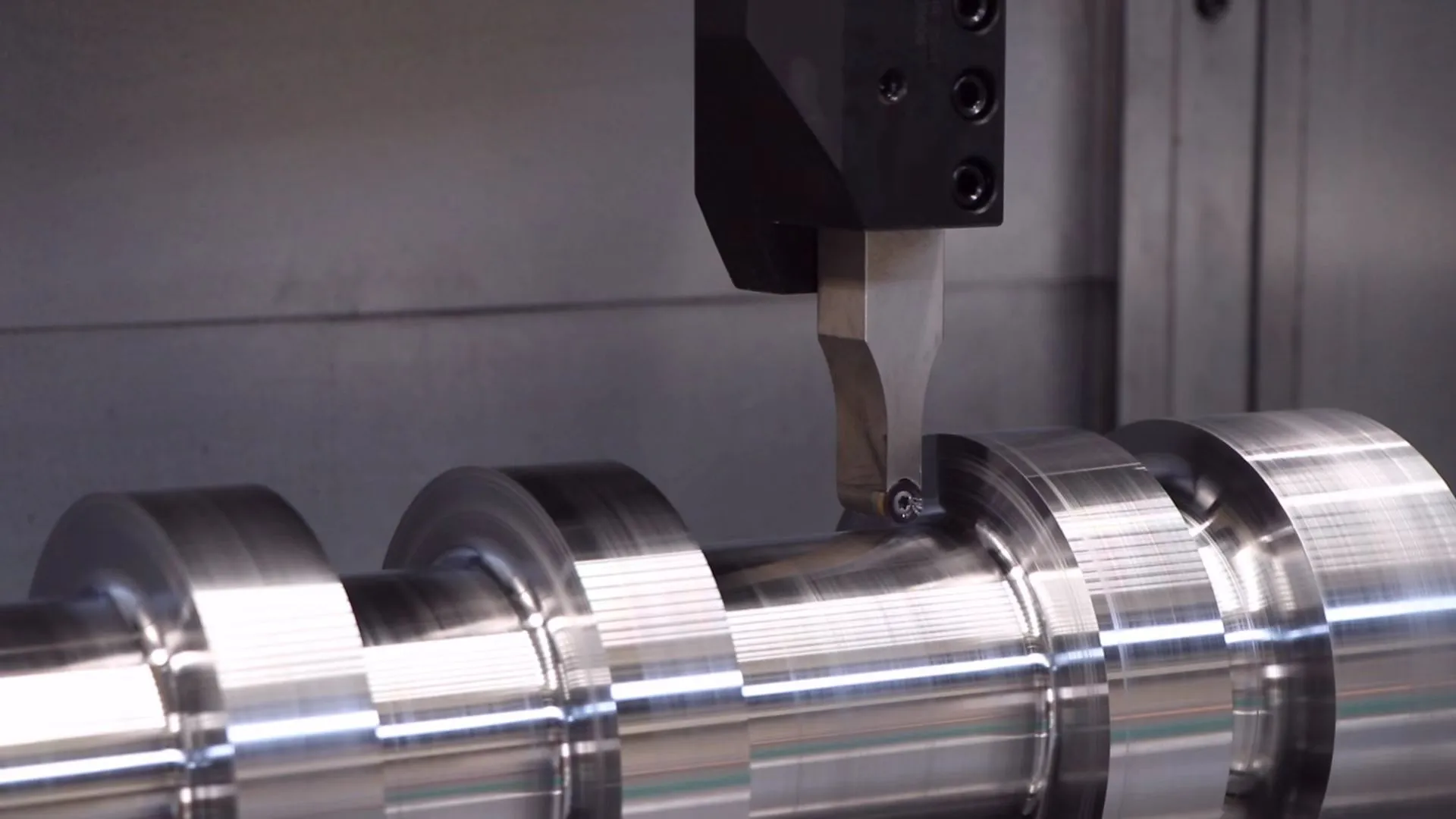

CNC milling removes different parts of the surface of the workpiece through the high-speed rotation of the milling cutter, the product to be processed is placed on the rotating spindle, and the direction of movement of the part is controlled through the spindle.

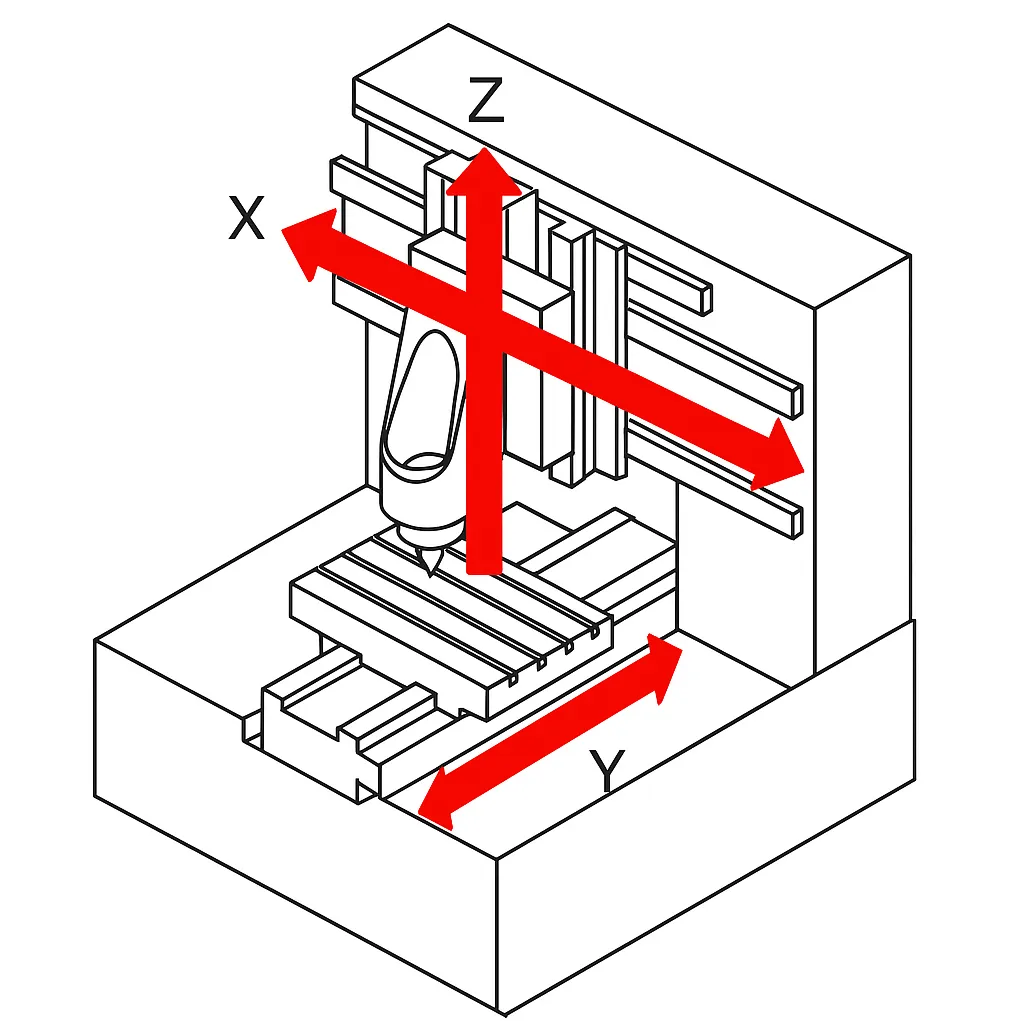

CNC milling machine will generally have 3-5 axes of motion, precision CNC milling machine may be equipped with more axes of motion, and finally through the upper (Z-axis) of the tool with the spindle (X-Y-axis) on the product in order to remove the different parts of the surface of the workpiece, to form the desired shape, so as to achieve a variety of precision parts production.

History and Evolution of CNC Milling

The development of CNC milling can be traced back to the 1950s, when computer technology was widely used in industry.In the early 1960s, CNC milling machines were rapidly popularized in various industrial fields, and the range of applications has been expanding in the continuous updating and improvement.

Unlike traditional milling machines, it has functions such as automatic tool change and automatic side milling, which can accomplish high-precision and complex shape machining. The machining task can be completed automatically by simply controlling the machine tool through CNC programming. With the passage of time, the machine tool is getting faster and faster, with higher and higher precision, and is able to process more and more kinds of materials.

How CNC Milling Works

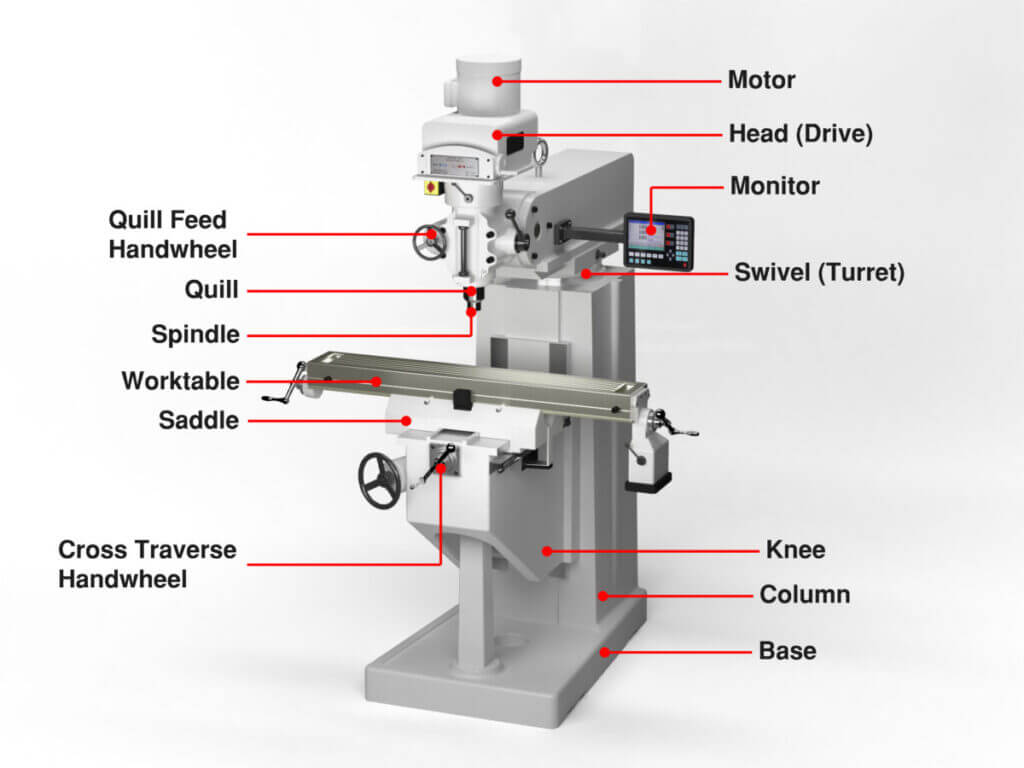

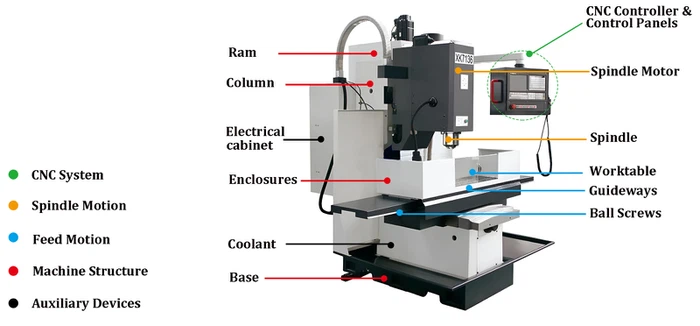

Understanding the different parts of a milling machine helps you to better understand the principle of machining, each milling machine manufacturer is different, for some parts will have some differences, but all will have these parts below:

CNC controller: it is equivalent to the core component of the whole milling machine, without it there is no automation as such, it is by accepting G-code commands from the computer to control the movement and cooperation between the different axes of the machine (X-Y-Z axes), it also controls the machine tool change and the release of coolant.

Spindle (Z-axis): It is located on top of the table, it controls the tooling, and the material on the table is machined by moving the fixed tool up and down.

Table (X-Y axis): it is fixed on the machine base, the general milling machine is moving back and forth from left to right, that is, we often say XY axis, for some specific parts milling machine can also add additional axes, such as adding a rotary axis, you can increase the number of axes 1-2 axes, generally known as 4-axis or 5-axis.

Tool magazine: in the processing of parts often because the product requires different processing methods such as roughing, finishing, etc., these need different tools to work, tool magazine for storage of different specifications of the tool, the convenience of the staff to switch and do not need to add additional from the amount of time saved.

Cooling system: for some materials such as steel, copper, stainless steel, etc., they will produce high heat in the machining process, if you do not take the necessary cooling measures, will not only lead to deformation of the workpiece and machining surface quality degradation, but also on the drill, milling cutter tools, such as life expectancy caused by a greater impact. Therefore, coolant is used to reduce the temperature generated during the machining process and to reduce the cutting force and wear.

Type of Milling Machine

Milling machine is a kind of widely used machine tool, mainly used for machining plane, groove, gear and other complex surface. According to different classification standards, milling machines can be divided into a variety of types, the following are common types and their characteristics:

Vertical Milling Machine

Vertical milling machine is a kind of metal cutting down on the surface of the workpiece through the interaction of rotary and linear motion of the cutting tool. This type of milling machine can perform plane milling, chamfering, hole machining and so on.

Vertical milling machine is generally composed of bed, spindle, feeding mechanism and so on. Among them, the spindle is the main component of vertical milling machine, which usually consists of motor, spindle box, spindle and spindle support. The feeding mechanism includes table feeding mechanism and cutting feeding mechanism.

Features: plane milling, chamfering, drilling, boring, tapping and so on.

Application Scenario: suitable for machining spiral groove, complex parts, large workpieces.

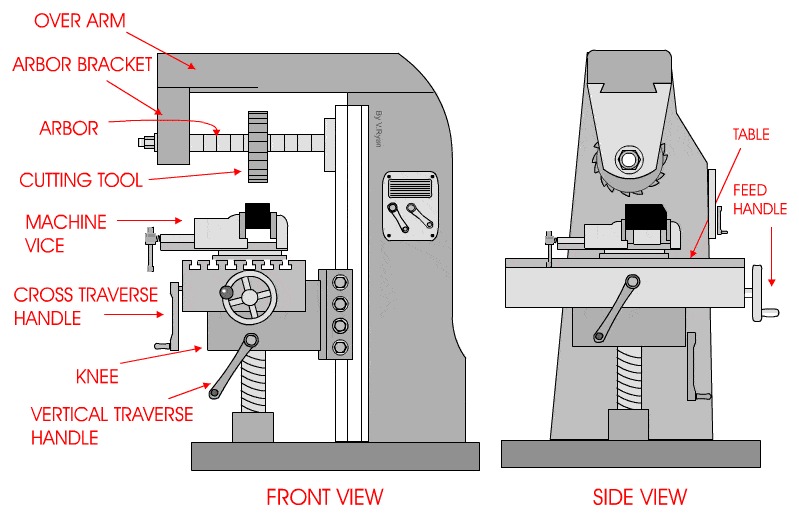

Horizontal Milling Machine

Horizontal milling machine is a kind of machine tool used for machining large parts. The components are the table, the feed unit, the spindle, and the cutting tool, etc., where the spindle is placed horizontally and the table and the tool move and cut in the horizontal plane.

Compared with vertical milling machines, the table of horizontal milling machines has the unique function of moving and rotating in the horizontal direction of the machine tool, which also provides an important guarantee of flexibility and adaptability in the machining process.

Features: good cutting stability, the structure of horizontal milling machine spindle is stable, the gravity of the workpiece is evenly distributed to the entire table during cutting, so it has good cutting stability, and it can also carry out multi-surface machining to improve machining efficiency.

Application Scenario: It is mainly used to process various large workpieces, such as ship bearing seat, automobile engine base, aviation engine parts, etc.

Gantry Milling Machine

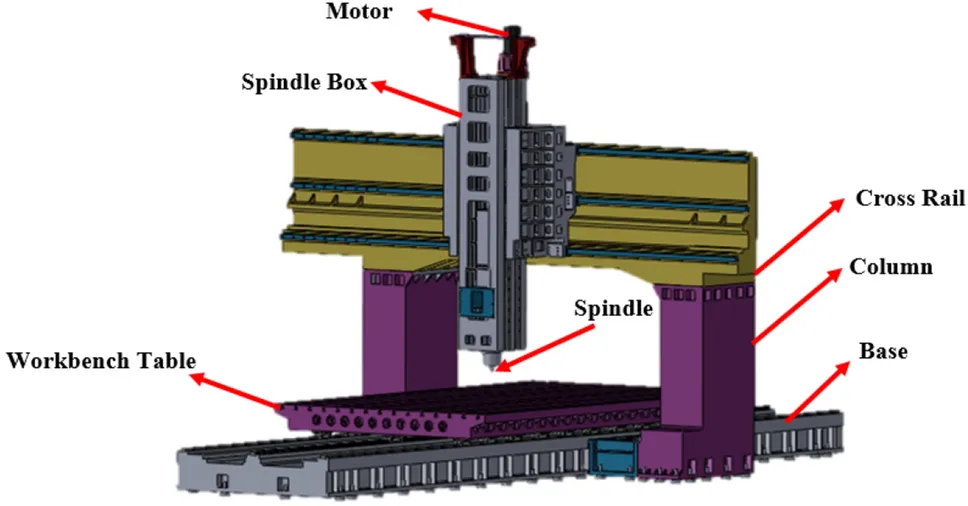

Gantry milling machine is a large machine tool which consists of gantry frame, table, spindle box, powerful feeding system, hydraulic system and electrical control system.

Mainly through the spindle rotation and table movement, to realize the workpiece for metal cutting processing. In machining, the spindle box drives the tool to rotate at a high speed, cutting, piercing or cutting on the workpiece, thus producing parts of different shapes.

Features: Cutting, perforating and cutting are suitable for machining large and complex parts.

Application Scenario: Machining of large molds, large gears, casting dies, stamping dies, etc.

CNC Milling Machine

CNC milling machine is a kind of control system with digital signals as instructions, the working principle is to convert digital signals into signals for machine tool control movement. The control system of CNC milling machine is composed of computer, CNC equipment, driver and actuator.

Users enter the processing graphics and processing parameters through the computer, the CNC system will automatically calculate the machine tool movement trajectory, and control motors, servo motors and other actuators in accordance with the predetermined trajectory of the movement, so as to complete the processing of the workpiece.

Features: High precision, high efficiency, high automation production, which can greatly improve production efficiency and reduce processing costs.

Application Scenario: In the aviation, aerospace, automotive, electronics, machinery and other fields to meet the processing needs of complex parts.

Each type of milling machine has its unique structure and application scenarios. Users can choose the most suitable type based on their specific processing needs. If you’re unsure about which processing method to choose, contact Future Parts. With over 20 years of industry experience, their experts can provide professional solutions for your product. Get in touch now!

Types of Materials and Properties

CNC milling can be done with a wide variety of materials, including metals, plastics, and composites. Each material has its own unique physical and chemical properties that are suitable for different machining needs:

Metallic materials: such as aluminum, steel, copper and iron, which have characteristics such as high strength and good corrosion resistance, and are suitable for manufacturing parts in aerospace, automotive and other sectors

Plastic materials: such as polypropylene (PP), polyvinyl chloride (PVC), polytetrafluoroethylene (PTFE), polyethylene (PE), etc., which have the advantages of light weight, corrosion resistance, insulation, low cost, etc., and are widely used in the fields of electronic products, household appliances, etc.

Composite materials: such as carbon fiber composites, glass fiber composites, etc., with light weight, high strength, corrosion resistance, etc., applicable to aerospace, automotive, sports equipment and other fields

Advantages of CNC Milling Machine

CNC milling, as an advanced machining technology, plays an increasingly important role in modern manufacturing. Below we will discuss in detail the several advantages of CNC milling.

1、High precision machining

Through the precise CNC system and advanced milling tools, it can realize extremely high precision machining. This is not only reflected in the dimensional accuracy of the workpiece, but also includes shape accuracy and positional accuracy. Therefore, it is very suitable for processing those parts that require very high precision, such as precision parts in aviation, aerospace and other fields.

2、High efficiency production

Compared with traditional milling processing, CNC milling has higher productivity, which can reduce manual intervention and realize continuous and stable processing. At the same time, CNC milling machine also has high cutting speed and feed rate, which also improves productivity.

3, Flexible

Can adapt to the processing needs of different workpieces. By adjusting the CNC program and tooling, you can easily achieve different shapes, sizes and materials of the workpiece processing. This makes a significant advantage in dealing with complex and variable machining tasks.

4, Reduce labor intensity

The use of CNC milling technology can greatly reduce the work intensity of the operator. Due to automation, the operator only needs to carry out simple program settings and monitoring.

In summary, CNC milling technology with its high precision, high efficiency, flexibility and low labor intensity advantages, in the modern manufacturing industry plays an important role, with the continuous development of technology, the future will play a greater role in the transformation and upgrading of the manufacturing industry.

Trusted CNC Milling Services – Future Parts

Future Parts delivers high-quality CNC machining services with ISO 9001 & ISO 14001 certified processes, ensuring precision, reliability, and environmental responsibility. Whether you need prototypes or production runs, our advanced machining expertise guarantees superior results for aerospace, automotive, and industrial applications. Get a quote today!

FAQs

How accurate is CNC milling?

CNC milling can be accurate to within a few microns, making it ideal for industries with high tolerance requirements, such as medical, aerospace and other precision parts.

What materials can CNC milling machines machine?

A variety of materials can be processed, including metals, plastics and composites, and you can contact our customer service to learn more about process-related materials.

What are the advantages of CNC milling machines over traditional methods?

CNC milling offers greater accuracy, faster production speeds and less reliance on labor than traditional milling methods.

Can CNC milling be used for mass production?

Yes, CNC milling is highly efficient in mass production, especially for parts that require high accuracy and consistency.