CNC Machining Material Selection Guide

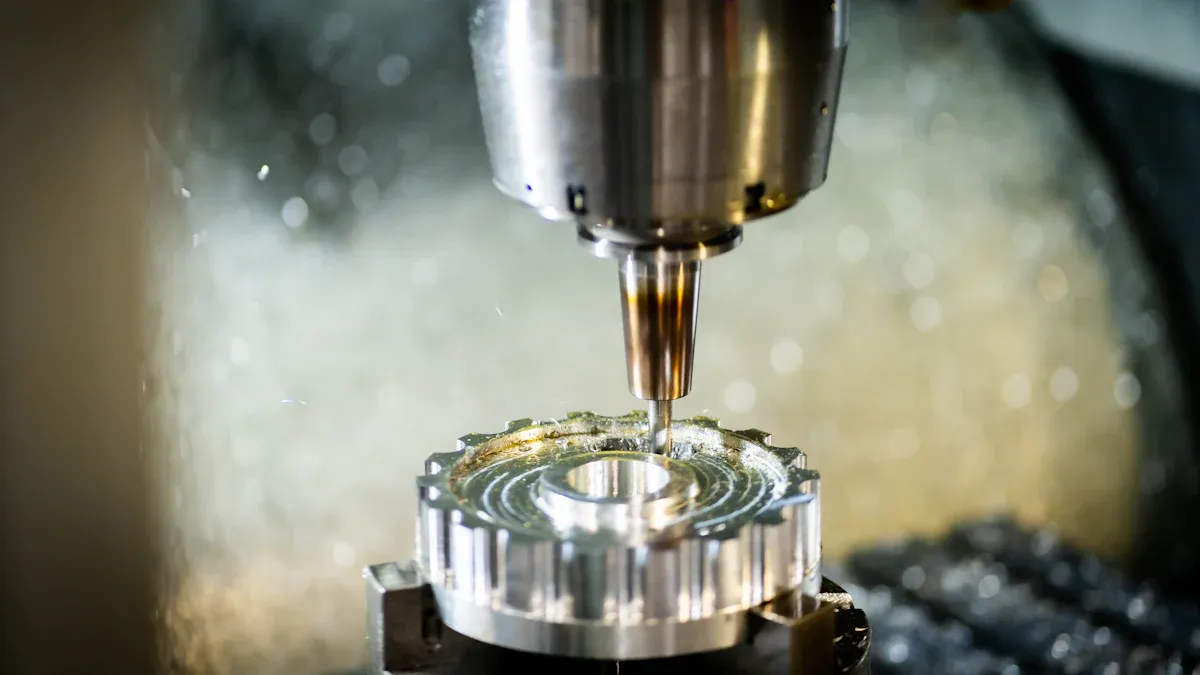

You need to match material properties to your part’s requirements, cost targets, and manufacturing capabilities. When you begin CNC machining material selection, focus on strength, machinability, and durability. Each material group offers unique benefits and challenges. For example, aluminum gives you high strength and easy machining, while titanium resists corrosion but wears tools quickly. Use the table below to compare common options and find the best fit for your project.

CNC Material Types

Metals Material

Metals are the most common materials in CNC machining. You use them for their strength, durability, and versatility. Here are the main types:Aluminum

Aluminum alloys are lightweight and strong. You find them in aerospace and automotive parts. They resist corrosion and conduct heat well. Aluminum is easy to machine, which helps you save time and money.Steel

Steel comes in many forms, such as stainless and carbon steel. Stainless steel resists corrosion and works well in medical devices and aerospace applications. Carbon steel is tough and affordable, making it ideal for machinery and construction.Copper Alloys

Copper and its alloys, like brass, offer excellent electrical and thermal conductivity. You use them for heat sinks, electrical connectors, and valves. Brass is easy to machine and has low magnetism.Magnesium

Magnesium is even lighter than aluminum. You use it for parts where weight matters most, such as aerospace and automotive components. Magnesium machines quickly but needs careful handling due to its flammability.Titanium

Titanium stands out for its strength-to-weight ratio and corrosion resistance. You see it in aerospace frames and medical implants. Machining titanium is challenging because it wears out tools fast.

CNC Plastics Material

Plastics offer flexibility, insulation, and resistance to chemicals. You choose them for lightweight parts and complex shapes.ABS

ABS is tough and impact-resistant. You use it for prototypes, housings, and consumer products.Acetal

Acetal (POM) is strong and slippery. You find it in gears, bearings, and precision parts.Acrylic

Acrylic is clear and shatter-resistant. You use it for display panels and lenses.Nylon

Nylon is durable and wear-resistant. You choose it for bushings, washers, and mechanical parts.PEEK

PEEK is a high-performance plastic. It resists chemicals and heat, making it suitable for medical and aerospace parts.PVC

PVC is chemical-resistant and affordable. You use it for fittings and fluid-handling components.Polycarbonate

Polycarbonate is tough and transparent. You find it in safety shields and electronic housings.Polypropylene

Polypropylene resists chemicals and fatigue. You use it for laboratory equipment and automotive parts.UHMW-PE

UHMW-PE is extremely wear-resistant. You choose it for liners, guides, and impact surfaces.Ultem

Ultem (PEI) offers high strength and heat resistance. You use it in electrical and medical applications.Compatibility

Not every finish works with every material. Some finishes, like anodizing, suit aluminum best. Others, such as powder coating, work on many metals and plastics. You need to check if your chosen finish matches your material.- Functionality: Surface finishes must meet the part’s functional requirements, such as wear or corrosion resistance.

- Material Compatibility: Some finishes are better suited for specific materials, e.g., anodizing for aluminum.

- Aesthetic Considerations: The desired appearance influences the choice of finish, such as gloss or matte.

Prototype & Test

Prototyping helps you validate your material selection before full production. You can catch design flaws and performance issues early. Follow these best practices to get the most from your prototypes:- Set clear design objectives. Know what you want to learn from each prototype.

- Choose materials that match the final part’s environment and use.

- Optimize your CAD models for easy machining. This reduces errors and saves money.

- Use rapid prototyping methods to speed up development. Technologies like CNC milling and 3D printing help you test ideas quickly.

- Test prototypes against required tolerances. Quality control ensures your part meets specifications.