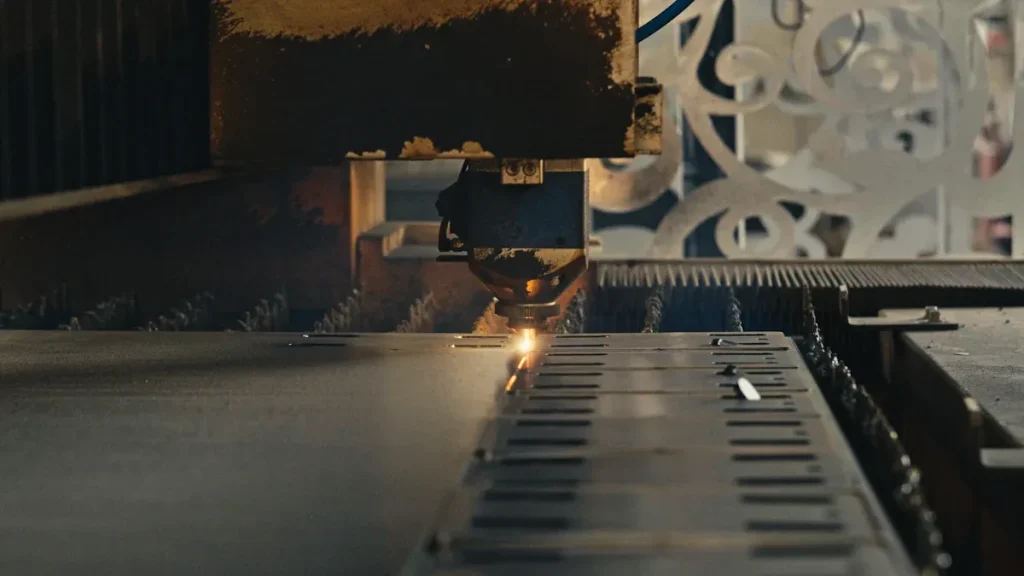

Laser cutting uses a strong light beam to cut or engrave materials with precision. This laser cutting technology creates clean edges and detailed shapes without the machine physically touching the material. Many companies prefer laser cutting because it is fast and produces less waste compared to traditional cutting methods. The global market for laser cutting is expanding rapidly, as shown in the table below:

| Metric | Value (USD Billion) | Year/Period |

|---|---|---|

| Laser processing market size | 7.17 | 2025 |

| Projected market size | 11.89 | 2032 |

| CAGR | 8.5% | 2025-2032 |

Key Takeaways

- Laser cutting uses a strong light beam to cut things. It does not touch the material. This makes smooth edges and detailed shapes.

- This way of cutting is fast. It saves material and makes less waste. Many industries use it because it saves money. These include car, airplane, and medical companies.

- Different lasers work best for different materials. Fiber lasers cut metal fast. CO2 lasers are good for wood and plastic. Nd:YAG lasers do detailed work on metal and ceramics.

- Some materials are not safe for laser cutting. Do not use PVC, ABS, or other dangerous things. They can make toxic fumes and hurt the machine.

- Safety is very important. Always wear safety gear. Make sure the room has good airflow. Get the right training before using laser cutting machines.

What Is Laser Cutting

Definition

Laser cutting uses a strong light beam to cut many materials. The laser points at the material and heats it up fast. The heat makes the material melt, burn, or react with oxygen. This creates a thin line and splits the material along a set path. The machine moves the laser head to follow the design.

How Laser Cutting Works:

- The laser source makes a strong beam.

- Mirrors or lenses point the beam at the material.

- The hot spot gets so hot that the material melts or turns to gas.

- The laser follows the design and connects the cuts.

- A computer system guides the laser for accuracy.

The machine does not touch the material during cutting. This keeps the edge sharp and stops the tool from wearing out. It also helps keep the area clean and lowers the chance of dirt.

Key Features

Laser cutting is known for being very exact and flexible. It can cut many shapes, even ones with tiny details. Computer controls help make sure every cut matches the design, even if it is hard.

| Aspect | Details |

|---|---|

| Cutting Accuracy | Can cut as close as a few microns; normal range is ±0.05 to ±0.2 mm (0.002 to 0.008 in) |

| Tolerances | Usually within ±0.1 mm (0.004 inches) or better; can be even closer with better machines |

| CNC Control | Makes sure the laser head moves right for each cut |

| Non-contact Cutting | No tool wear, so cuts stay the same over time |

| Heat-Affected Zone | Small HAZ means less bending or warping than other cutting methods |

| Advanced Beam Control | Uses special optics to keep the beam strong and cuts steady |

| Repeatability | CNC and steady settings give the same results every time, even for tricky shapes |

Laser cutting has many good points:

- The process does not touch the material, so the edge stays sharp.

- No oils or lubricants are needed, so the material stays clean.

- The machine makes smooth edges, so less extra work is needed.

- Maintenance costs are low because tools do not break.

- The process saves time and money, especially for big jobs.

Laser cutting works on many things like sheet metal, plastics, and wood. It gives clean results and can handle both easy and hard projects. Many businesses use laser cutting services when they need very exact and repeatable cuts.

How It Works

Laser Cutting Process

Laser cutting uses a focused light beam to cut materials very accurately. First, workers get the material ready and put the design into the machine. They set things like how strong and fast the laser should be. The machine then does these steps:

- Material Preparation: Workers put the material, like metal or wood, on the cutting bed. They make sure it will not move.

- Design Setup: The design file goes into the computer system. The operator checks and changes settings for the material’s type and thickness.

- Laser Beam Generation: The machine makes a laser beam with a special light source. This happens when particles inside the laser get excited and give off light.

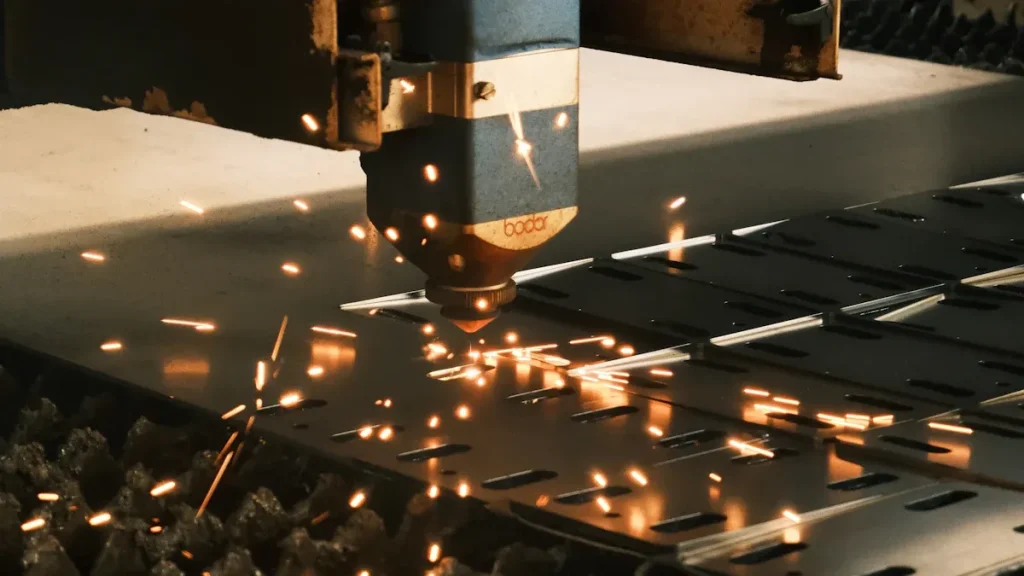

- Beam Focusing: Lenses or mirrors make the laser beam very small and strong on the material’s surface.

- Parameter Adjustment: The operator sets the laser’s power, speed, and focus spot. These depend on the material and how good the cut should be.

- Cutting Action: The laser heats the material very fast. The heat melts, burns, or turns the material into gas. An assist gas, like oxygen or nitrogen, blows away melted or burned parts and keeps the cut clean.

- Motion Control: The computer moves the laser head or table to follow the design. This makes sure every cut matches the design.

- Finishing Steps: After cutting, workers take out the finished parts. They might clean or smooth the edges if needed.

Tip: Picking the right assist gas can make the cut better and stop heat from spreading too much.

The science behind this uses laser light made by excited particles, focusing the beam to make it strong, and using heat to change the material. There are different ways to cut, like melting, burning, or using oxygen to help burn metals. For brittle things, the laser can even make cracks that split the material along a line.

Main Components

A laser cutting machine has many important parts. Each part helps the process work well and safely. The table below shows the main parts and what they do:

| Component | Role in Laser Cutting Process |

|---|---|

| Laser Source (Fiber or CO₂ Laser) | Makes the strong laser beam needed to cut things like metal or wood. |

| Cutting Head | Focuses and points the laser beam at the material; has a nozzle, focus lens, and tracking system. |

| CNC Control System | Moves the laser head and table to make sure cuts are exact. |

| Motors | Move the laser head and table to the right spots. |

| Machine Tool | Gives a strong frame for cutting; types include gantry and cantilever machines. |

| Laser Lens | Focuses the laser beam to a tiny point for cutting. |

| Beam Delivery System | Uses mirrors or fiber optics to send the laser beam from the source to the cutting head. |

| Motion Control System | Helps move the laser head and material for exact cutting paths. |

| Work Table and Material Handling | Holds and moves the material; may have clamps, rotary tables, or conveyors. |

| Cooling System | Keeps the machine cool by taking away heat during use. |

| Exhaust and Filtration System | Removes smoke, fumes, and dust to keep air clean and protect the machine. |

| Software and Control Interface | Lets users load designs, set cutting settings, and watch the process in real time. |

| Protective Enclosures and Safety Features | Protects workers from laser light and fumes; has safety locks and emergency stops. |

- The laser source makes the beam, and the beam delivery system sends it to the cutting head.

- The CNC control system and motors move the laser head and table to follow the design.

- The cooling system and exhaust system keep the machine safe and working well.

- Software lets people load designs and change settings easily.

- Safety features keep everyone safe in the work area.

Laser cutting machines use smart technology to make clean, exact cuts on many materials. The mix of good control, strong lasers, and easy-to-use software makes this process popular for jobs that need detailed and repeatable results.

Types & Techniques

Laser Types

Laser cutting uses different kinds of lasers for many jobs. The three main types are CO2 lasers, fiber lasers, and Nd:YAG lasers. Each one is good for certain tasks.

| Feature | CO2 Laser | Fiber Laser | Nd:YAG Laser |

|---|---|---|---|

| Efficiency | Moderate | High (~25% electro-optical) | Moderate (~20% pumping) |

| Lifespan | Moderate | Long (~100,000 hours) | Shorter (flash lamp wear) |

| Maintenance | Higher (more parts to replace) | Low (minimal part replacement) | High (flash lamps need regular replacement) |

| Cost | Lower upfront, higher running cost | Higher upfront, lower running cost | Lower upfront, higher ongoing maintenance |

| Applications | Non-metals, thin metals | Metals: steel, aluminum, copper, brass | Metals, plastics, ceramics |

| Precision | Good for non-metals | High, especially for metals | Excellent for detailed work |

| Speed | Moderate | Fast, especially for metals | Slower, best for precision |

| Footprint | Larger, traditional setup | Compact, modern design | Larger, traditional setup |

Fiber lasers are great for cutting metals like steel and aluminum. They work fast and do not need much fixing. CO2 lasers are best for things like wood, acrylic, and leather. Nd:YAG lasers are very exact and can cut metals, plastics, and ceramics, but they need more care and do not last as long.

Tip: Fiber lasers help save money because they last longer and use less power.

Cutting Methods

Laser cutting uses different ways to cut each material. The most common ways are listed below:

| Laser Cutting Method | Technology & Wavelength | Suitable Materials | Power & Precision | Applications | Results & Edge Quality | Cost & Maintenance |

|---|---|---|---|---|---|---|

| CO2 Lasers | Gas laser, 10.6 µm IR | Wood, acrylic, leather, thin metals | 25-100+ watts, moderate precision | Wood, plastics, thin metals | Good for non-metals, moderate edge quality | Lower cost, higher maintenance |

| Fiber Lasers | Solid-state, 1.064 µm | Metals, thermoplastics, glass, wood | Up to 6 kW+, high precision | Metal fabrication, engraving | Clean, precise edges, fast cutting | Higher cost, low maintenance |

| Nd:YAG/Nd:YVO Lasers | Crystal lasers, ~1.064 µm | Metals, non-metals, ceramics | High power, versatile | Medical, military, specialized | Versatile, costly | High cost |

| Direct Diode Lasers | Compact diode lasers | Thin metals, other materials | Moderate power, efficient | Fast, low-cost jobs | Clean cuts, smooth edges | Cost-effective, compact |

- CO2 lasers are good for plastics, wood, and leather, but you need to keep the air clean.

- Fiber lasers are best for cutting metal fast and making smooth edges.

- Nd:YAG lasers are used for careful work on metals, plastics, and ceramics.

- Direct diode lasers are small and save energy, so they are good for thin materials.

Laser cutting gives smooth edges and neat finishes. Each way works best for certain jobs, so it is important to pick the right one.

Laser Cutting Materials

Suitable Materials

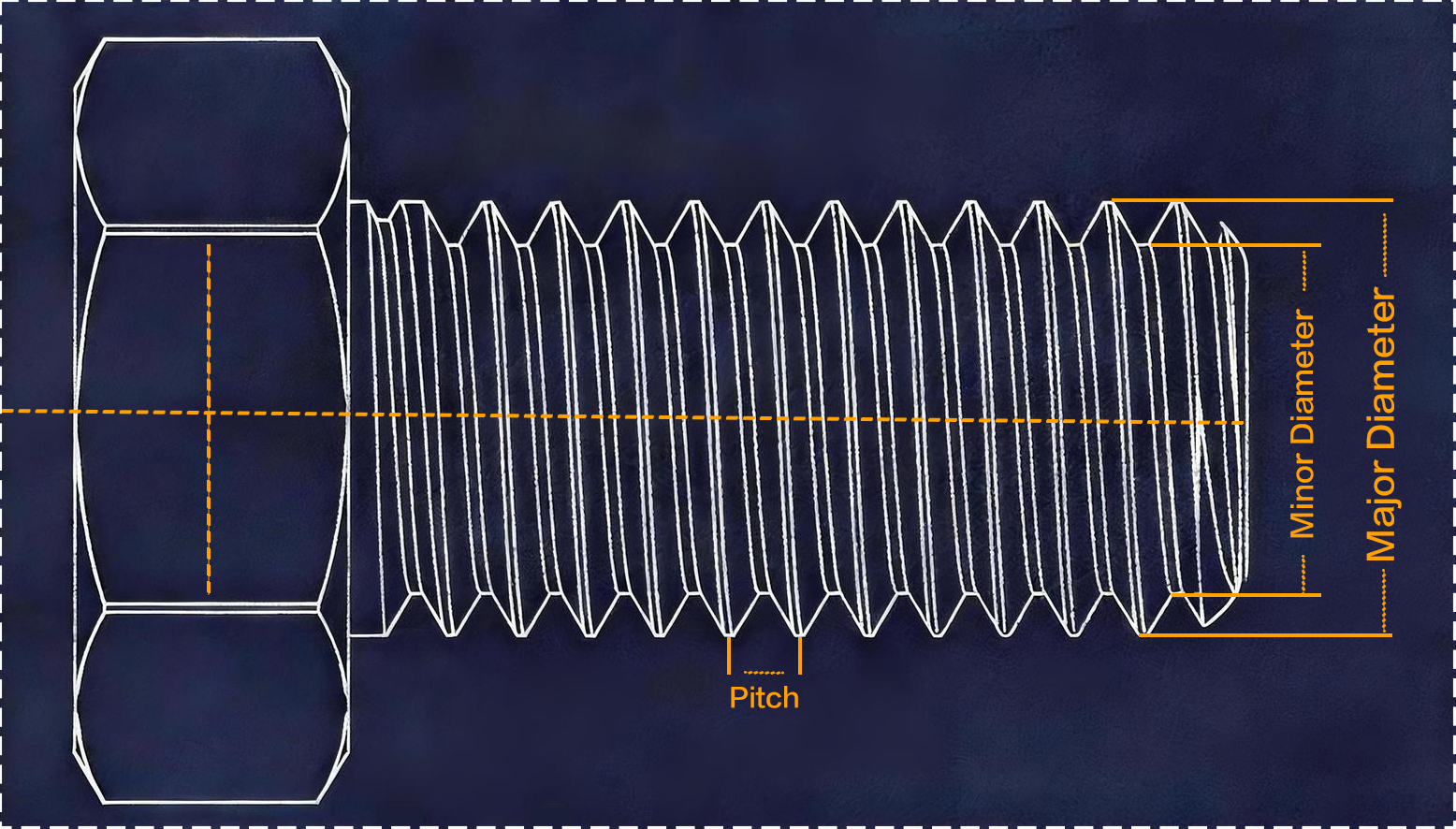

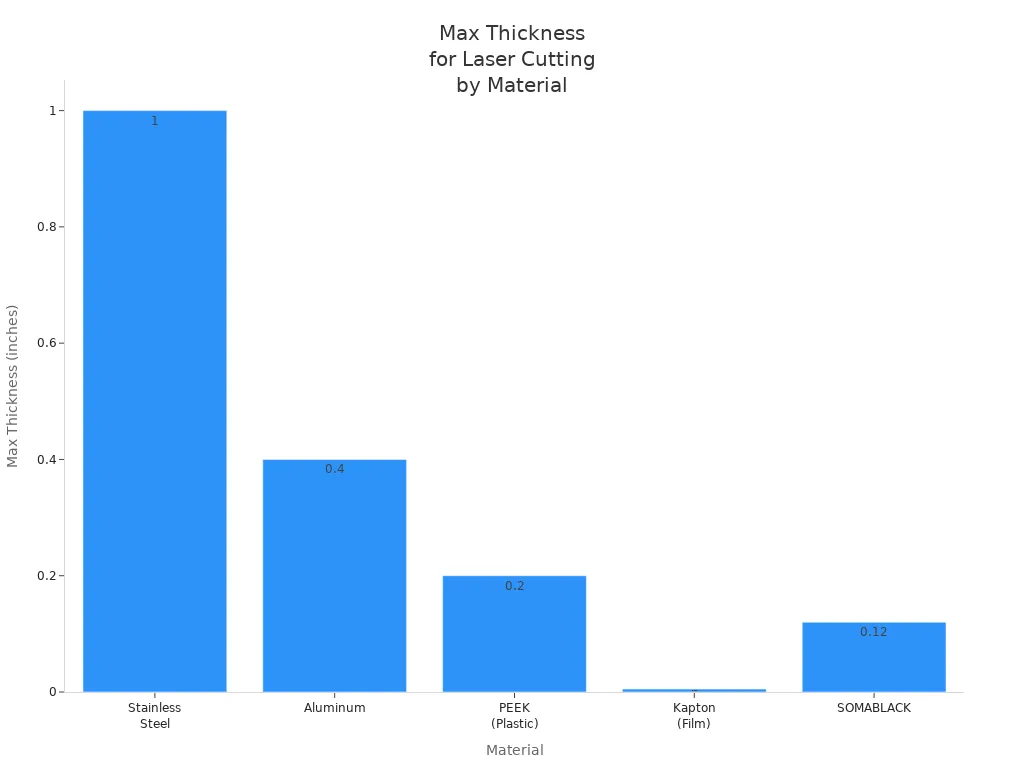

Laser cutting works on many different materials. Metals like stainless steel and aluminum are common choices. These metals can be cut in many thicknesses. Stainless steel can be as thin as 0.012 inches (0.3 mm). It can also be thicker than 1 inch (25 mm). Aluminum is usually between 0.04 inches (1 mm) and 0.4 inches (10 mm). Plastics like PEEK and Kapton film can be cut too, but only if they are thin.

| Material | Typical Thickness Range for Laser Cutting |

|---|---|

| Stainless Steel | 0.012 inches (0.3 mm) up to over 1 inch (25 mm) |

| Aluminum | 0.04 inches (1 mm) to 0.4 inches (10 mm) |

| PEEK (Plastic) | Up to about 0.2 inches (5 mm) |

| Kapton (Film) | 0.001 to 0.005 inches (25 to 125 microns) |

| SOMABLACK | Up to 0.12 inches (3 mm) or more |

Other good materials are wood, acrylic, glass, ceramics, stone, fabrics, and rubber. Each material acts differently when cut. Wood and acrylic can be cut into detailed shapes with smooth edges. Metals need the right kind of laser and enough power. Fabrics like cotton and polyester cut easily and do not fray.

Note: Materials that do not reflect much light and can handle heat well are best. They absorb the laser energy better. This makes cleaner cuts and less damage.

Unsuitable Materials

Some materials are not safe or do not work well with laser cutting. These can make toxic fumes, hurt the machine, or give bad results.

- PVC (Poly Vinyl Chloride): Makes dangerous chlorine gas and can break machines.

- ABS (Acrylonitrile Butadiene Styrene): Gives off harmful fumes like hydrogen cyanide.

- Fiberglass: Makes toxic gases and tiny dust that is bad to breathe.

- Polycarbonate (thick): Melts and turns yellow, so the edges look bad.

- Foam core boards with adhesives: The glue can make unsafe fumes.

Other unsafe materials are:

- Things with halogens (like PVC)

- Epoxy or phenolic resins

- Leather with chromium (VI)

- Carbon fiber with epoxy

- PTFE (Teflon)

- Beryllium oxide

- Flame-retardant things with bromine

Tip: Always check your material before you start. Do not use things that make toxic gases or can break the laser machine. Use good ventilation and safety gear if you are not sure what the material is.

Applications & Safety

Common Uses

Laser cutting helps many businesses make things quickly and with detail. Companies use it to cut, engrave, or shape materials for cars, planes, electronics, and buildings. The table below shows how different businesses use laser cutting:

| Industry | Typical Laser Cutting Applications |

|---|---|

| Automotive | Sheet metal body parts, seat fabrics, and exact parts for making lots of cars fast |

| Aerospace | Parts for planes and spaceships like engine covers, blades, fasteners, wings, and heat shields |

| Medical Equipment | Parts for machines, tools for surgery, and implants |

| Electronics | Circuit boards, cutting silicon wafers, engraving, and making tiny holes |

| Construction | Steel parts for buildings like plates and connectors |

Factories use laser cutting to make custom parts like brackets, panels, and covers. In hospitals, it helps make implants and tools that need to be very exact. Small shops use laser cutting to make signs, jewelry, and decorations.

Pros and Cons

Laser cutting has many good points:

- It can make detailed shapes and smooth edges.

- It cuts fast, so work gets done quicker and costs less.

- The machine does not touch the material, so tools last longer and things stay clean.

- Machines can do the same job over and over with little waste.

But there are some problems too:

- The machines cost a lot to buy.

- Some things, like thick metal or PVC, are hard or unsafe to cut.

- Workers need special training to use and fix the machines.

- Cutting thick stuff uses more power and can slow things down.

| Advantage | Explanation |

|---|---|

| Precision | Makes very detailed and high-quality cuts. |

| Speed | Can cut up to 10 times faster than a bandsaw. |

| Cost-effectiveness | Saves money by working faster and not wearing out tools. |

Safety & Environment

Laser cutting machines can be risky if not used right. The biggest dangers are hurting your eyes or skin, fire, electric shock, and breathing in bad fumes. People should wear safety goggles, gloves, and special clothes. Good air flow and filters help get rid of smoke and dust. Fire extinguishers and emergency stops should be nearby.

| Hazard Type | Description | Protective Measures |

|---|---|---|

| Eye/Skin Injuries | The laser can hurt your eyes and skin | Wear goggles, gloves, and protective clothes |

| Fire Hazards | The heat can start fires | Keep the area clean and have a fire extinguisher |

| Inhalation of Fumes | Cutting makes smoke and dust | Use good air flow and filters |

Laser cutting uses a lot of electricity, especially for thick or tough things. It also makes waste like scrap metal and dust. Companies can help the planet by recycling, using machines that save energy, and following safety rules.

Tip: Always check what you are cutting to stop bad fumes and keep everyone safe.

Getting Started

New users should do these things to use a laser cutter safely:

- Only people who are trained should go in the laser cutter room.

- Keep doors shut so the air system works well.

- Check and empty the scrap tray before and after using the machine.

- Clean the laser bed with a brush or vacuum to get rid of small pieces.

- Hold the material in place with pins or tape.

- Take away all tools and materials when you finish.

- Take an online class or join a group to learn more.

Many websites have free designs and lessons for beginners. Starter kits and guides help new users practice and get better.

Laser cutting is very exact and can cut many things like metal, plastic, and wood. People need to be careful and pick safe materials. Some materials can make dangerous fumes, so do not use them. It is important to focus the beam right and set up the machine well. Using assist gases helps make the cuts clean.

- Always make sure the material is safe and check the machine.

- Think about getting training and help before buying a machine.

- Try maker spaces or watch online videos to learn more.

FAQ

What materials work best with laser cutting?

Laser cutting works best on sheet metal, wood, acrylic, and some plastics. Many people use laser cut wood for craft projects. Metal cutting laser machines can cut steel and aluminum. Always make sure the material is safe before you start.

Is laser cutting safe for beginners?

Laser cutting is safe if you follow the safety rules. Beginners should wear goggles and keep the area clean. Never leave the machine running by itself. Many laser cutting services teach new users how to use the machines.

How accurate is a laser cutting service?

A laser cutting service can be very exact. Most machines cut within ±0.1 mm. This helps make detailed designs in sheet metal and wood.

Can a metal cutting laser cut thick materials?

| Material | Typical Max Thickness |

|---|---|

| Steel | 1 inch (25 mm) |

| Aluminum | 0.4 inch (10 mm) |

A metal cutting laser can cut thick steel or aluminum. Thicker pieces need more power and slower cutting speeds.