What is SLM 3D Printing?

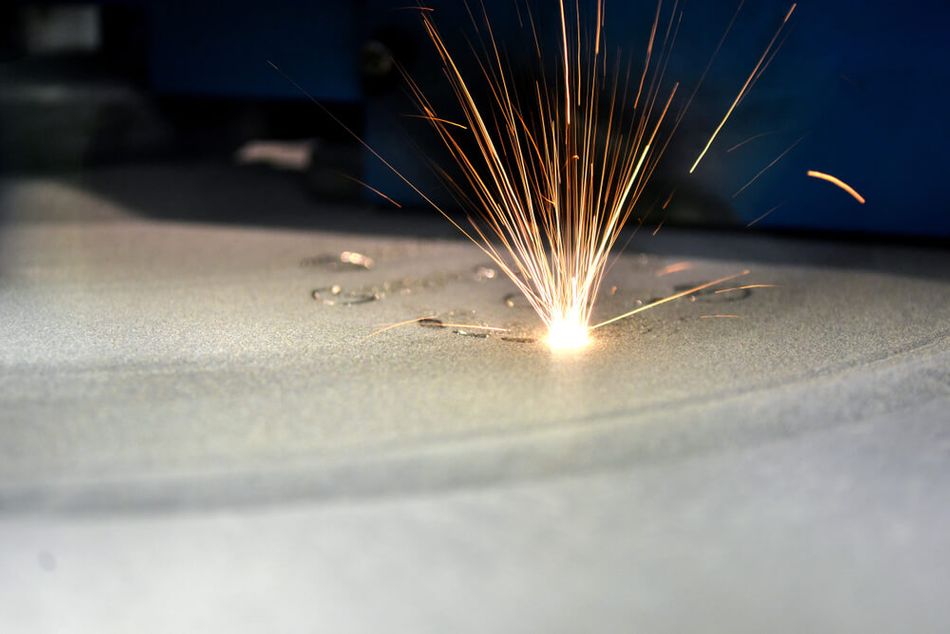

SLM (Selective Laser Melting) is an additive printing technology. It completely melts metal powder through laser and then builds metal parts layer by layer. The accuracy of parts printed by slm is generally ±0.3mm, and it can reach up to ±0.2mm through precision processing methods.

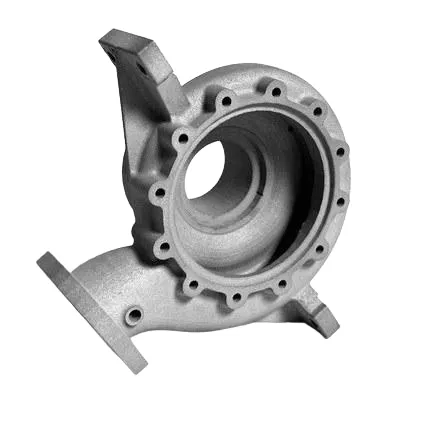

During the printing process of SLM, as it melts powder to build products, the structure between metals is completely integrated when forming the shape of each layer. The products manufactured are also high-strength parts, which is why it is popular in the automotive and aerospace industries.

The process of SLM 3D printing mainly consists of five stages: design, preparation, laser melting, layer-by-layer construction and post-processing. Post-treatment is required because the surface of the products produced by SLM may have a somewhat rough feeling. Polishing or electrochemical treatment can improve the surface smoothness.