Alloy steel and carbon steel are popular with customers in modern manufacturing, but their differences can make or break your project. Alloy steel gains superior strength and corrosion resistance through the addition of elements such as chromium and nickel, while carbon steel is known for its affordability and ease of processing.

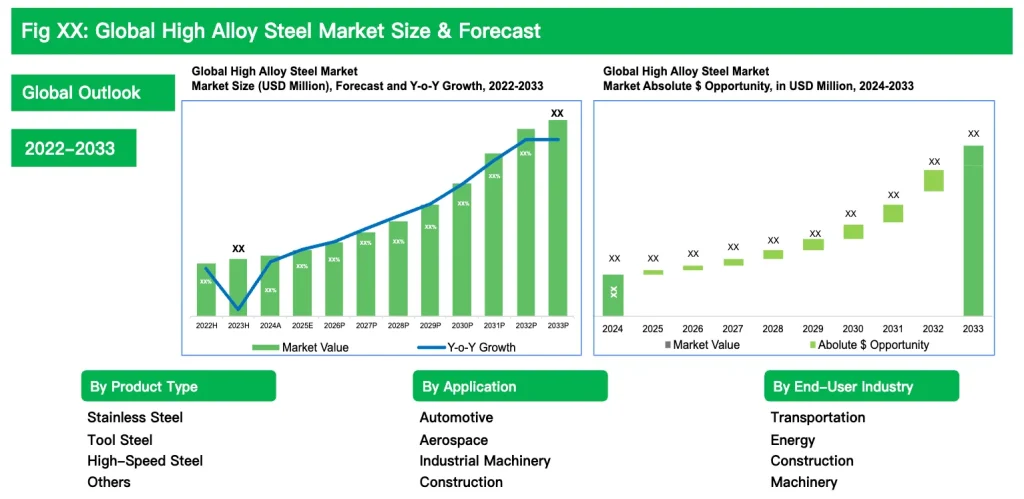

The alloy steel market is expected to reach USD 152.93 billion by 2025, growing 3.2% from 2024, with this growth primarily driven by the automotive, construction, and aerospace industries. In CNC machining, alloy steels are favored for their excellent mechanical properties and machining stability, but carbon steels still dominate in cost-sensitive applications.

The key question is: Which material should you choose for your project?

This article will provide you with a detailed comparison of the differences between the two steels, an analysis of the advantages and disadvantages, and how to choose a steel to help you make the most informed material choice in 2025, whether you’re looking for high performance or controlling budgetary costs.

What is Alloy Steel?

Definition and Composition

Alloy steel is made by mixing iron with other metals. These metals are called alloying elements and include chromium, nickel, and manganese. Each of these metals can make steel better. For example, chromium prevents rust, while vanadium makes it stronger. The amount of carbon in alloy steel also changes its hardness. Alloy steel works better than low carbon steel in harsh conditions.

A study shows how these metals affect steel strength:

This table shows how balancing metals makes steel strong and useful. Source: PMC Article

Key Characteristics

The special properties of alloy steel make it stand out. It is very strong and therefore well suited for heavy work. It does not rust easily and therefore lasts longer. Changing the composition of alloy steel can make it lighter or stronger. For example, low-alloy steel is easier to handle, while high-strength alloy steel is perfect for large projects.

In addition, alloy steel can withstand extremely hot or cold temperatures. This is why it is used in airplanes and power plants. Unlike carbon steel knives, which tend to rust, alloy steel retains its luster and lasts longer.

Common Applications of Alloy Steel

Alloy steel is used in many industries. It is ideal for automotive parts, construction materials and airplane parts. High-strength alloy steel is particularly popular because it is very strong.

The demand for alloy steel is growing.The market is valued at USD 22.27 billion in 2025 and is likely to grow to USD 31.05 billion by 2034. This growth is mainly from industries such as automotive, aircraft, and construction. To name a few:

- Automobile manufacturers use it for engines and gears.

- Builders use it for beams and supports.

- Aircraft manufacturers use it for frames and blades.

These uses illustrate why alloy steel is so important today.

What is Carbon Steel?

Definition and Composition

Carbon steel is composed primarily of iron and carbon. The carbon content ranges from 0.05% to 2.0%. This content determines the hardness and strength of carbon steel. Unlike alloy steels, carbon steel does not contain additional metals such as chromium or nickel. Its simple composition makes it very popular.

There are three main types of carbon steel: mild, medium and high carbon. Mild steel, also known as low carbon steel, contains less than 0.3% carbon. It is soft and easy to mold. Medium carbon steel has a carbon content of 0.3% to 0.6%. It is stronger, but still flexible. High-carbon steel has more than 0.6% carbon. It is very hard, but breaks more easily.

Key Characteristics

Carbon steel is cheap and versatile. It is strong and durable. However, it will rust if left in air or water for too long. It is not as rust-proof as alloy steel.

Low carbon steel is easy to weld and form. It is therefore ideal for construction projects. Medium carbon steel is strong, making it ideal for making mechanical parts. High carbon steel is very hard and can be used for tools such as knives.

Another advantage of carbon steel is that it can be recycled. Old carbon steel can be melted down and reused, which helps the environment.

Common Applications of Carbon Steel

Carbon steel is used in a wide range of industries because of its strength and affordability. It is common in construction, automobile manufacturing and factories. Examples of its uses are as follows

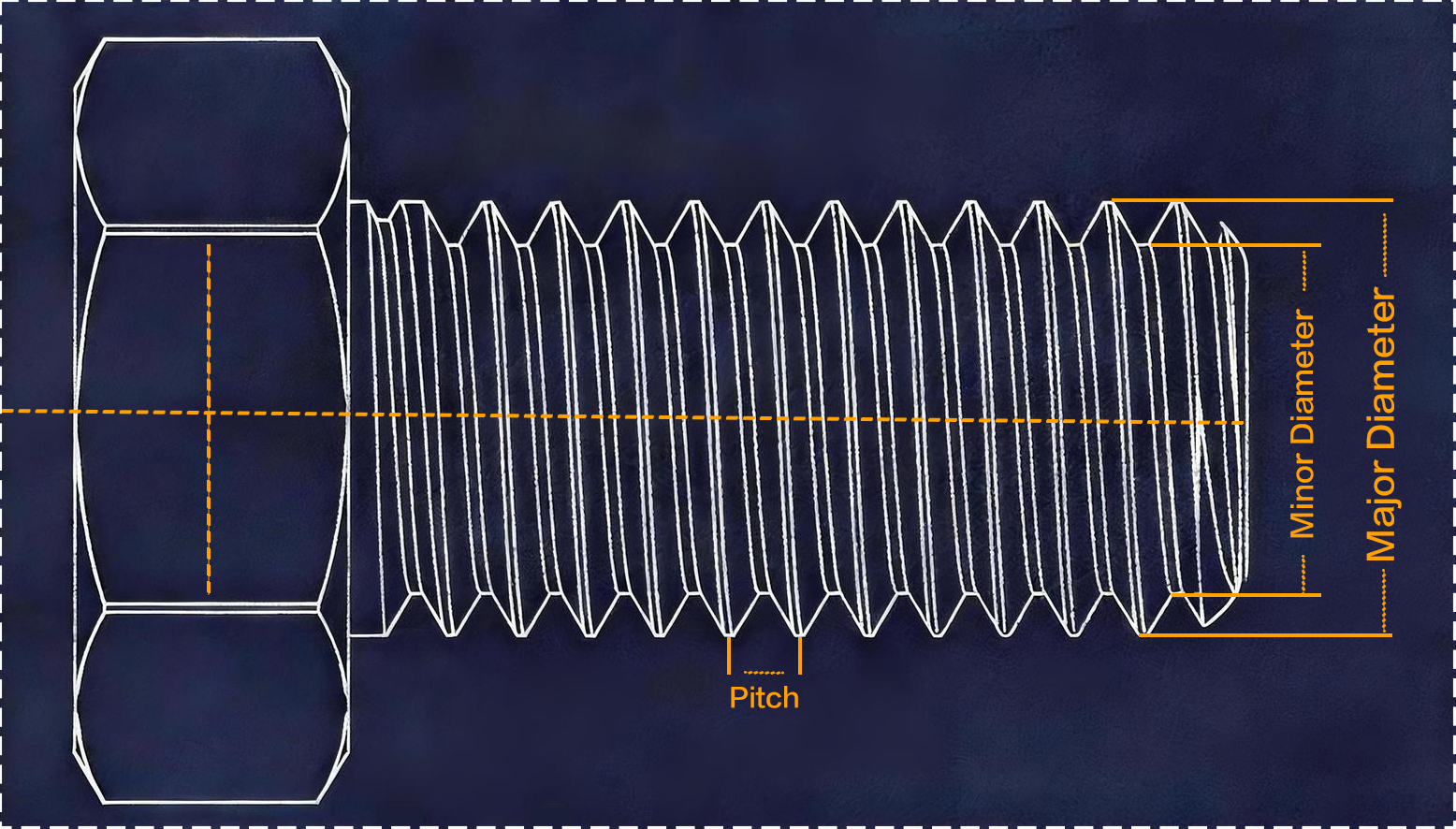

- Structural Components: such as bolts, beams and fasteners.

- Machinery Parts: crankshafts and sprockets, etc.

- Tools and Equipment: tools such as cutters and cutting tools.

By 2025, carbon steel will account for $25 billion in sales in the ferroalloys market. The use of carbon steel in construction and machinery demonstrates its importance today. If you need strong materials for construction or machinery, carbon steel is a good choice.

Key Differences Between Alloy Steel and Carbon Steel

Composition

The main difference between Alloy Steel vs Carbon Steel is the material they are made of. Alloy steel contains additional metals such as chromium, nickel and vanadium. These metals make alloy steel stronger, prevent it from rusting, and help it cope with hot or cold temperatures. For example, airplanes use magnesium alloy because it is both strong and lightweight.

Carbon steel is even simpler. Its main components are iron and carbon, with carbon content ranging from 0.05% to 2.0%. This makes it cheaper and easier to manufacture. Low carbon steel is soft and easy to mold. Medium carbon steel is stronger, but still bends well. High-carbon steel is very hard, but breaks more easily.

Strength and Durability

Alloy steel is usually stronger and lasts longer than carbon steel. Additional metals such as chromium and vanadium make it tougher and less prone to wear and tear. This makes it an ideal material for automotive parts, building beams, machinery and more.

Tests have shown that alloy steel remains strong even under harsh conditions. For example

These studies show that alloy steel stays strong even in extreme places, making it a good choice for important jobs.

Carbon steel is also strong, but it has limitations. If it gets wet, it can rust, which accelerates wear and tear. Medium carbon steel is tougher than low carbon steel, but not as strong as alloy steel. Carbon steel knives, for example, are sharp and sturdy, but they need to be maintained to avoid rusting.

Cost Comparison

Cost is another major difference between Alloy Steel vs Carbon Steel. Carbon steel is cheaper because it is simpler to manufacture. This makes it a favorite for larger projects like construction and machinery. Low carbon steel is especially affordable and easy to work with, making it perfect for tight budgets.

Alloy steel costs more because it contains additional metals such as chromium and nickel. However, alloy steel has the advantage of not rusting and being very strong, making the higher price tag worth it. Industries such as automobiles and airplanes often choose alloy steel because they need materials that will last for a long time.

Uses in Various Industries

Steel is important in many industries. The choice of alloy steel or carbon steel depends on the needs of each industry. Understanding their uses will help you choose the right steel.

Oil and Gas Industry

The oil and gas industry needs robust materials to cope with harsh conditions. Alloy steel can withstand high pressure and does not rust easily. It can be used for pipes, drill collars and valves. For example, magnesium alloy steel is a good choice because of its strength and light weight.

Food Processing Industry

In food processing, cleanliness and rust prevention are very important. High alloy stainless steel is an excellent choice for tanks, mixers and cutting tools. It is perfect for this industry as it stays clean and does not rust.

Construction Industry

The construction industry makes extensive use of carbon steel because it is both strong and inexpensive. Low carbon steel is used to make beams, frames and bars. It is easy to form and weld, making it ideal for large projects. Medium carbon steel is used where extra strength is needed.

Alloy steel is not common in construction. However, low alloy steel is sometimes used when more strength or rust resistance is needed.

Medical Tools and Devices

In the medical field, alloy steel is the best choice. It is strong, safe for humans and has a long service life. Surgical tools, implants and medical devices often use alloy steel. Magnesium alloy steel is popular because it is lightweight and strong enough for implants.

Quick Comparison of Industry Uses

Here’s a simple table showing how alloy and carbon steel are used:

Every industry has different needs. The choice between Alloy Steel and Carbon Steel depends on cost, strength and the environment. Understanding these uses will help you choose the right material.

Advantages and Disadvantages of Each

Pros and Cons of Alloy Steel

Alloy steel has many advantages for tough jobs. It is very strong and has a long service life. Metals such as chromium and vanadium allow it to withstand heavy loads well. These metals also help it resist wear and tear. This is why it is perfect for cars and airplanes. Another advantage is that it does not rust easily. Unlike carbon steel, alloy steel holds up well in wet places. You can also change the combination of alloy steel to suit different needs.

However, alloy steel has some disadvantages. It costs more than low carbon steel because of the extra metal used. The fabrication process is also more complex, which adds to the price. This may not be suitable for projects with smaller budgets. In addition, it is more difficult to machine. Its hardness makes it more difficult to cut, weld, or shape than softer materials such as low-alloy steel.

Pros and Cons of Carbon Steel

Carbon steel is an inexpensive and practical option for many projects. It is simple and affordable, especially for large buildings. Low carbon steel is easy to form and weld, and it is also relatively common in Sheet Metal Fabrication. This makes it ideal for beams, frames and other building components. Medium carbon steel is stronger but still flexible, making it ideal for use in machines. High carbon steel is very hard and is ideal for tools such as knives.

However, carbon steel has some drawbacks. It can rust if it gets wet, which limits its use in damp places. Although it is strong, it is not as tough as alloy steel. For example, carbon steel wears out faster in harsh conditions compared to magnesium alloy steel or other high-grade steels.

Which is better, alloy steel or carbon steel?

Whether you choose alloy steel or carbon steel depends on your needs. Both types of steel have their own advantages and are suitable for different purposes. To choose the best one, consider strength, cost, and longevity.

Strength and Durability

For tough jobs, alloy steel is stronger and lasts longer. Additional metals such as chromium and vanadium make them tough and resistant to damage. Magnesium alloy steels, for example, are lightweight but strong, making them ideal for aircraft and medical implants. Low-alloy steels also work well in extreme heat or pressure conditions, which is why they are used in the oil and gas industry.

Carbon steels are strong but don’t last as long in harsh environments. Medium carbon steel is suitable for mechanical parts, while low carbon steel is easy to form and weld. However, tools such as carbon steel knives need to be carefully maintained as they can rust in wet environments.

Cost and Budget

If saving money is paramount, carbon steel is the better choice. Carbon steel is popular for construction projects because of its simple design and lower manufacturing costs. Low carbon steel is particularly suitable for beams and frames. Alloy steel costs more but lasts longer and is less prone to rust, making it worthwhile in the long run.

How Future Parts Can Help You Succeed

Whether your project requires high-strength, corrosion-resistant alloy steel or economical and practical carbon steel, Future Parts can provide you with a one-stop solution from prototype manufacturing to mass production. We are committed to using professional technical knowledge and efficient manufacturing processes to accurately transform your innovative designs into high-quality physical parts. Get a free quote here easily, or if you need to learn more about these materials or our services, please contact our sales representatives at any time.

How to Choose the Right Steel for Your Needs in 2025

Industry-Specific Recommendations

Different industries require different types of steel. Here’s how to choose according to your field:

Automotive Industry

Automobiles use customized steel for lighter and safer. Alloy steel is used for strong parts such as door panels. Low-alloy steel is also used as it balances strength and cost.

Construction Industry

Builders use low carbon steel for beams and frames. It is cheap and easy to work with. Low-alloy steel lasts longer and is less likely to rust in harsh weather.

Aerospace and Medical Fields

Magnesium alloy steel is lightweight and strong, making it ideal for aircraft. In the medical field, alloy steel is used for tools and implants because it is safe and durable.

Food Processing

High-alloy stainless steel is best suited for food tools and containers. It does not rust and stays clean. Carbon steel is rarely used because it is prone to rust.

Emerging Trends in Steel Usage

The world of steel is changing rapidly. Here are some trends to watch for in 2025:

More Tailored Steel Products

Custom steel and aluminum are popular in automobiles. They make cars lighter and safer, which improves fuel efficiency.

Sustainability and Recycling

Recycling carbon steel helps protect the planet and reduces costs. Recycled steel is both environmentally friendly and suitable for many industries.

Better Alloy Compositions

New alloy steels are stronger and lighter. Magnesium-alloyed steels, for example, are ideal for aircraft and medical tools.

Smart Manufacturing

SLS 3D printing and artificial intelligence are improving steel production. These methods can customize steel for specific needs.

Focus on Corrosion Resistance

Industries need rust-resistant materials. Harsh environments such as oil and gas require alloy steels.

Conclusion

Choosing between Alloy Steel vs Carbon Steel in 2025 comes down to balancing performance needs with budgetary constraints. Carbon steel offers excellent value for construction and general fabrication applications, while Alloy Steel vs Carbon Steel offers superior strength and corrosion resistance for demanding environments such as aerospace and the automotive industry.

The steel market continues to grow, with carbon steels maintaining their position in cost-sensitive projects and alloy steels expanding in high-performance applications. As manufacturing trends shift towards customization and sustainability, both materials will play a vital role in different areas.

At Future Parts, we understand that choosing the right steel is just the first step. Whether you need an affordable carbon steel or an alloy steel with advanced properties, our team of experts can provide comprehensive consultation to help you select the best material for your specific application. From prototyping to full-scale production, we offer precision manufacturing solutions to turn your designs into high-quality components.

FAQs

1. What is alloy steel? How is it different from carbon steel?

Alloy steel is made by mixing iron with metals such as chromium or nickel. These metals make it stronger and prevent it from rusting. Carbon steel consists mainly of iron and carbon. It is simpler, cheaper and commonly used in construction projects.

2. Can carbon steel rust?

Yes, carbon steel will rust when it comes in contact with water or air. It does not contain chromium, which prevents rusting. To keep your carbon steel tools safe, store them in a dry place or coat them.

3.Are carbon steel knives better than alloy steel knives?

Carbon steel knives are sharp and easy to sharpen. But they will rust if not cared for. Alloy steel knives don’t rust and last longer in wet areas. Choose carbon steel for sharpness or alloy steel for durability.