7075 vs 6061 Aluminum Snowmobile Parts

Why Your High-Performance Snowmobile Parts Must Be CNC Machined from Aerospace-Grade 7075 T6 Aluminum

For serious snowmobilers, race teams, and commercial operators across Europe, modifications are driven by the need for uncompromising reliability and safety in extreme cold and high-impact conditions. Selecting the right material is the first step toward a successful CNC custom motorcycle parts project.

In the world of custom fabrication, two aluminum alloys perpetually compete for dominance: 6061-T6 (the general-purpose workhorse) and 7075-T6 (the high-strength, aerospace-grade champion).

As a leading CNC Machining Specialist focused on specialized powersports components, we offer an in-depth, engineering-focused comparison of these two materials for your snowmobile and ATV/UTV upgrades.

Core Difference: Yield Strength and Fatigue Resistance (The Snowmobile Performance Factor)

In applications like suspension arms, steering columns, or frame reinforcements, parts must endure high-speed impacts, continuous vibration, and immense torque. In these scenarios, the mechanical differences between materials directly translate into safety and lifespan.

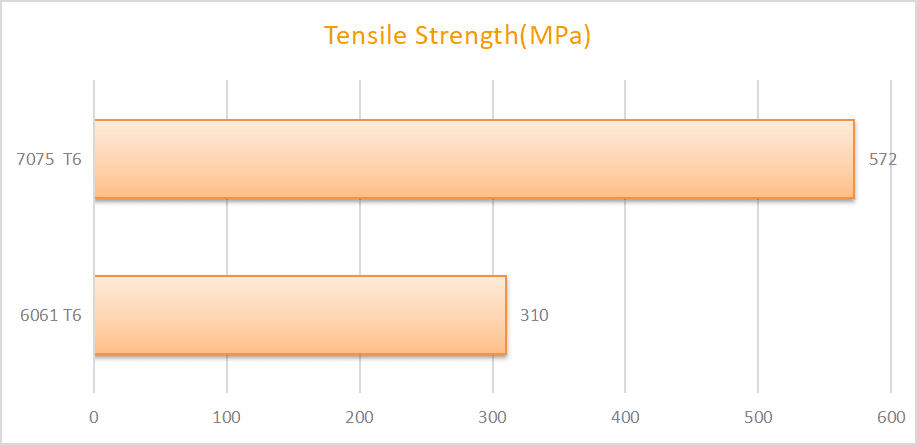

📈 7075 T6 vs 6061 T6 Mechanical Properties Comparison

| Property (T6 Temper) | 7075-T6 (Aerospace Grade) | 6061-T6 (General Purpose) | Significance for Snowmobile/ATV Upgrades |

| Yield Strength | Extremely High: Approx. 503 MPa (73 ksi) | Medium: Approx. 276 MPa (40 ksi) | ✅ 7075 Dominates. This determines when the part permanently bends or deforms. Crucial for resisting jumps and hard hits. |

| Tensile Strength | High: Approx. 572 MPa (83 ksi) | Medium: Approx. 310 MPa (45 ksi) | The ultimate resistance to breaking under tension or stretching. |

| Fatigue Resistance | Excellent | Good | ✅ 7075 Superior. Better performance under the high-frequency vibrations common in snowmobiles. |

| Weldability | Poor (Not Recommended) | Excellent (Easy to Weld) | Custom parts are often one-piece CNC; welding is usually avoided for critical high-strength aluminum parts. |

Engineering Insight: For performance snowmobile and ATV suspension upgrades, Yield Strength is the most critical metric. 7075-T6 is nearly twice as strong as 6061-T6, allowing us to design components that are significantly lighter yet structurally stiffer.

Pros & Cons: When to Choose 7075 for Custom ATV/Snowmobile Parts

| 7075-T6 Advantages (Performance Focus) | 7075-T6 Challenges (Manufacturing & Cost) |

| Maximum Strength-to-Weight Ratio: Essential for competitive racing and deep-snow climbing where every gram matters. | Higher Cost: Both the raw material and the complex CNC tooling required increase the final price point. |

| Superior Hardness & Rigidity: Resists abrasion and maintains tighter tolerances under extreme stress better than 6061. | Lower Corrosion Resistance: Due to higher copper/zinc content, 7075 must receive a proper protective finish (like Type III Hard Anodizing) for use in moisture/salt environments. |

| Exceptional Cold-Weather Reliability: Maintains its mechanical integrity in the freezing temperatures of Nordic climates. | Difficult to Machine: Requires high-end CNC equipment, precise speeds/feeds, and specialized cooling to prevent tool wear and chatter. |

Conclusion: Making the Right Material Choice for Your CNC Custom Motorcycle Parts

7075 vs 6061 Aluminum Snowmobile Parts

When consulting with our clients, we make material selections based on function, risk, and budget:

1. Choose 7075-T6 When: (Performance is Non-Negotiable)

- Snowmobile: Steering posts, suspension linkages, drive components, or any part whose failure would cause a catastrophic failure.

- ATV/UTV: Racing A-Arms, heavy-duty ATV suspension components, or custom differential mounts under high torque stress.

2. Choose 6061-T6 When: (Cost-Effectiveness is Key)

- Non-critical components, mounting brackets for accessories (lights, bags), spacers, or parts that are low-stress and may require field welding.

At FP, we deeply understand the CNC machining characteristics of both materials. We are not just manufacturers—we are your engineering partners, ensuring your custom parts never compromise in polar environments.

Submit your drawings immediately to request a customized quote.